Researchers at the University of Illinois Urbana-Champaign have developed a method to create structures that can transform from flat 2D shapes into curved 3D forms using low-energy activation. Aerospace Ph.D. student Ivan Wu and his advisor Jeff Baur combined continuous carbon fiber 3D printing with an energy-efficient resin system to address the challenge of transporting large structures like satellite dishes into space.

The process uses a 3D printer to create bundles of carbon fibers, each about the diameter of human hair, which are compressed and partially cured with ultraviolet light. The printed design is then molded with liquid resin and frozen until needed. When activated with low-energy heat, a chemical reaction called frontal polymerization cures the material into the desired 3D shape.

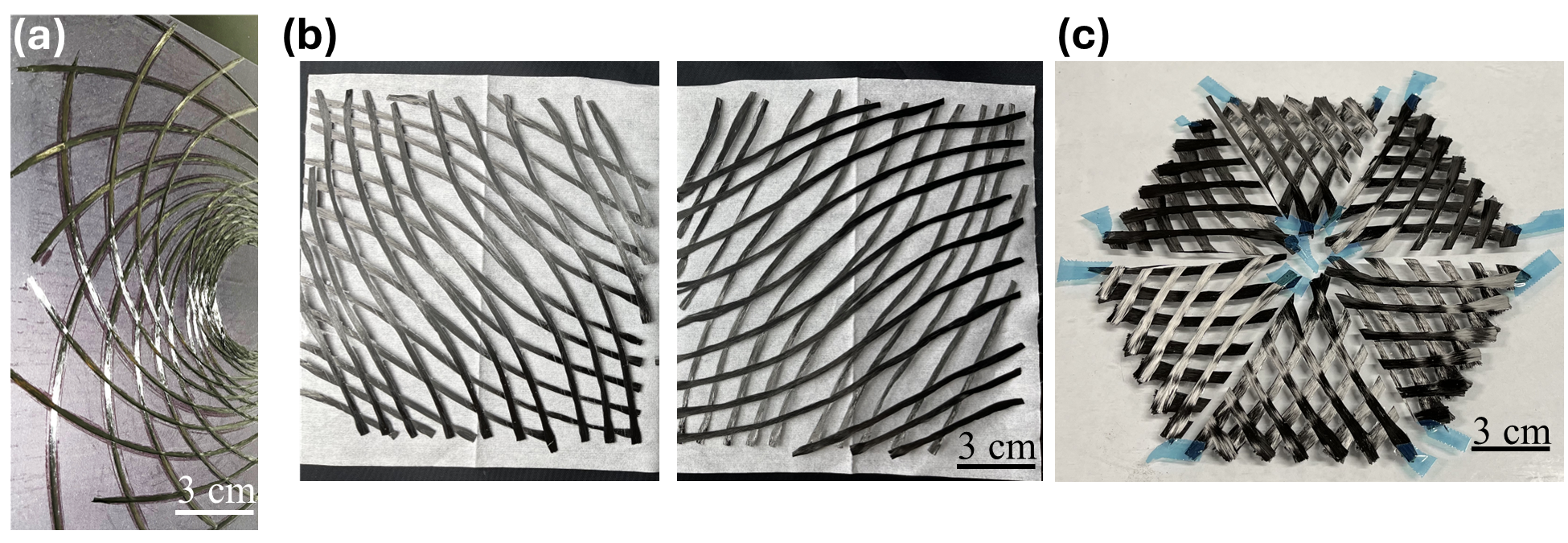

“For me, the first challenge was to solve the inverse problem,” Wu said. “You have a design for the 3D shape you want, but what is the 2D pattern to print that results in that shape? I had to write mathematical equations to describe the shapes to print the exact pattern.” Wu successfully created five different configurations including a spiral cylinder, twist, cone, saddle, and parabolic dish.

The method draws inspiration from kirigami, a Japanese art form that uses both cuts and folds. Wu noted that while the current stiffness levels aren’t adequate for final space structures, the activated shapes can serve as molds for manufacturing higher-stiffness components. The research, supported by the Air Force Research Laboratory, was published in Additive Manufacturing with DOI: 10.1016/j.addma.2025.104911.

Source: aerospace.illinois.edu