Daniel Rau, an assistant professor of mechanical engineering at the University of Wyoming, has received a $198,932 grant from the National Science Foundation to research 3D printing of soft materials. The grant, awarded through NSF’s engineering research initiation program, will fund Rau’s study of why current 3D printing processes produce unstable results when attempting to print elastomers and other flexible materials.

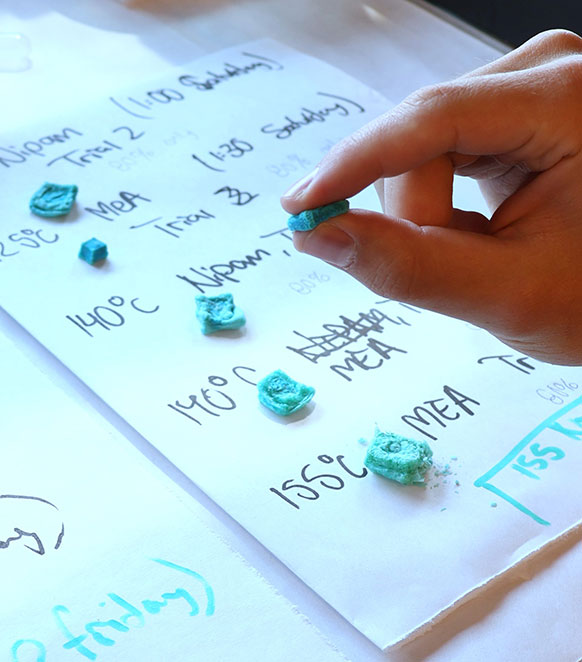

Current 3D printing technologies primarily produce hard, brittle plastic items, leaving soft material applications largely unexplored. Rau’s research project, titled “Improving the Vat Photopolymerization 3D-Printing of Soft Elastomers Through a Deeper Understanding of Process Dynamics,” focuses on understanding why additive manufacturing processes create warped blobs rather than functional products when printing rubber-like materials.

The research will employ two specialized techniques: photorheology and X-ray photon correlation spectroscopy (XPCS). Rau is collaborating with researchers at Brookhaven National Laboratory in New York, where he will use a 2.5-kilometer synchrotron to study the curing process of photopolymers at a microscopic level. “This particular additive manufacturing process deals with a really unique class of materials called photopolymers. They’re liquid; you hit them with UV light — think of really strong sunlight — and they solidify,” Rau says.

The research aims to create guidelines for manufacturing processes tailored to soft materials, with potential applications in biomedical devices, wearable technology, and protective equipment. Rau, who joined UW’s Department of Mechanical Engineering in fall 2024, notes the potential for medical applications: “There’s a lot of potential. You know, the human body is very soft. So, there are a lot of things the human body likes soft, whether it’s implants or wearable devices.”

Source: uwyo.edu