Anisoprint, a leading innovator in composite 3D printing technology, has recently undergone significant developments aimed at enhancing its manufacturing capabilities and expanding its global footprint. The company’s transition to manufacturing operations in China marks a strategic decision to leverage the region’s renowned manufacturing expertise and supply chain efficiency. According to Ryan Liu, the new CEO of Anisoprint, the move to China was motivated by various factors beyond cost considerations.

“China is the world’s manufacturing hub, and it’s not just because of cost,” says Ryan. “The quality standards of Chinese suppliers have become one of the highest in the world due to intense competition.”

This sentiment is echoed by Fedor Antonov, the company’s newly appointed CTO, who emphasizes the role of China’s manufacturing ecosystem in facilitating rapid production scale-up.

“China’s supply chain capabilities and competitive landscape have enabled us to establish a robust production line in a fraction of the time compared to our previous endeavors,” explains Fedor. “With the support of experienced local talent and efficient logistics, we have streamlined our manufacturing processes to meet growing demand.”

Ensuring Quality Control and Consistency

With the accelerated production pace in China, maintaining stringent quality control measures becomes paramount. Anisoprint has implemented comprehensive quality assurance protocols to uphold product integrity and consistency throughout the manufacturing process.

“Our approach to quality control is disciplined and meticulous,” affirms Ryan. “We have invested in experienced personnel and state-of-the-art facilities to uphold the highest standards of quality assurance.”

Fedor elaborates on the company’s quality control strategy, emphasizing the collaboration between European engineering expertise and local manufacturing capabilities.

“Quality control is discipline, in both meanings,” says Fedor. “With the guidance of our experienced engineers from Europe and the expertise of our local team in China, we have established robust quality control measures to ensure consistency and reliability in every product.”

Expansion Plans and Innovation Goals

Anisoprint’s expansion efforts extend beyond manufacturing, with plans underway to establish a new 8000 square meters factory in Suzhou, China. This strategic move aims to further bolster the company’s production capacity and foster innovation in composite 3D printing technology.

“The upcoming expansion represents a significant milestone in our growth journey,” states Ryan. “With a modern facility and access to a vibrant industrial ecosystem, we are poised to accelerate innovation and deliver cutting-edge solutions to our customers.”

Fedor echoes this sentiment, highlighting the synergistic benefits of the company’s location and partnerships.

“Our new facility in Suzhou provides an ideal environment for innovation and collaboration,” says Fedor. “With the support of local authorities and industry partners, we are confident in our ability to drive technological advancements and achieve our growth objectives.”

Research and Development Initiatives

Anisoprint’s commitment to innovation extends to its research and development endeavors, particularly in the exploration of new material profiles and composite materials. Fedor outlines the company’s research priorities and strategies aimed at advancing composite 3D printing technology.

“Our research focuses on enhancing productivity, expanding material offerings, and optimizing part performance,” explains Fedor. “By leveraging thicker fibers for higher deposition rates and exploring high-temperature engineering materials, we aim to push the boundaries of composite 3D printing capabilities.”

Software Enhancements and Future Vision

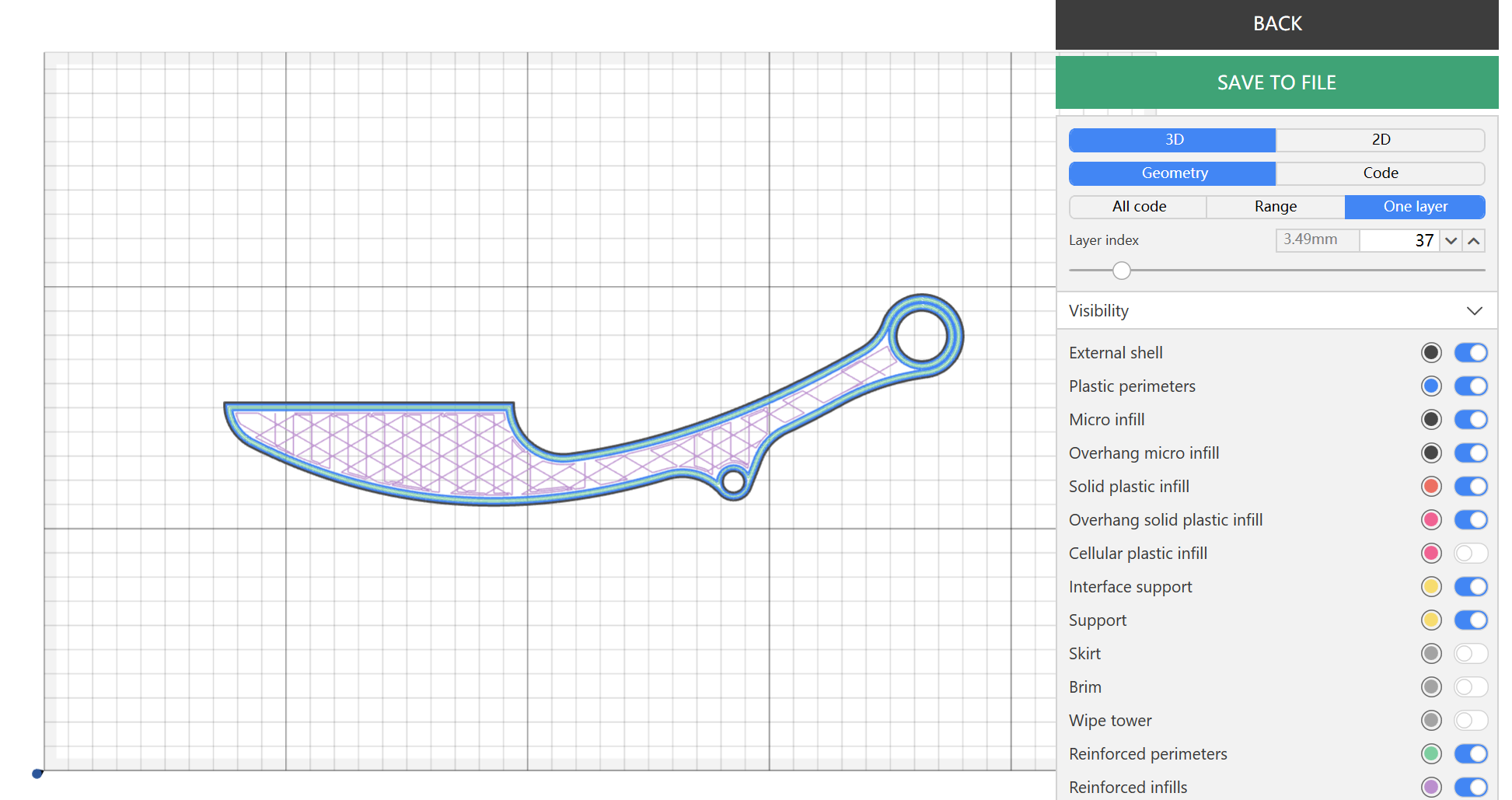

Anisoprint’s software platform, Aura, plays a pivotal role in optimizing the 3D printing workflow and enhancing user experience. Ryan provides insights into the upcoming features of Aura 3 and its implications for users.

“Aura 3 represents a significant advancement in our software capabilities,” says Ryan. “With features such as topology optimization and Aura Connect integration, users can expect enhanced functionality and streamlined workflow management.”

Looking ahead, both Ryan and Fedor express confidence in Anisoprint’s trajectory and emphasize their commitment to driving innovation and achieving strategic milestones.

“We are excited about the future of Anisoprint and the opportunities that lie ahead,” says Ryan. “With ongoing fundraising efforts and a clear vision for growth, we are well-positioned to lead the next wave of innovation in composite 3D printing.”

Fedor shares this optimism, underscoring the company’s focus on overcoming technological challenges and capitalizing on emerging opportunities.

“Challenges create opportunities, and we are ready to seize them,” affirms Fedor. “By leveraging our expertise, partnerships, and relentless pursuit of excellence, we are confident in our ability to shape the future of composite 3D printing.”

In conclusion, Anisoprint’s recent developments underscore its commitment to innovation, quality, and growth in the field of composite 3D printing. With a strategic manufacturing transition, expansion plans, and ongoing research initiatives, the company is poised to redefine industry standards and drive technological advancements. By leveraging its expertise and fostering collaborative partnerships, Anisoprint aims to empower customers with cutting-edge solutions and cement its position as a leader in the global 3D printing landscape.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.