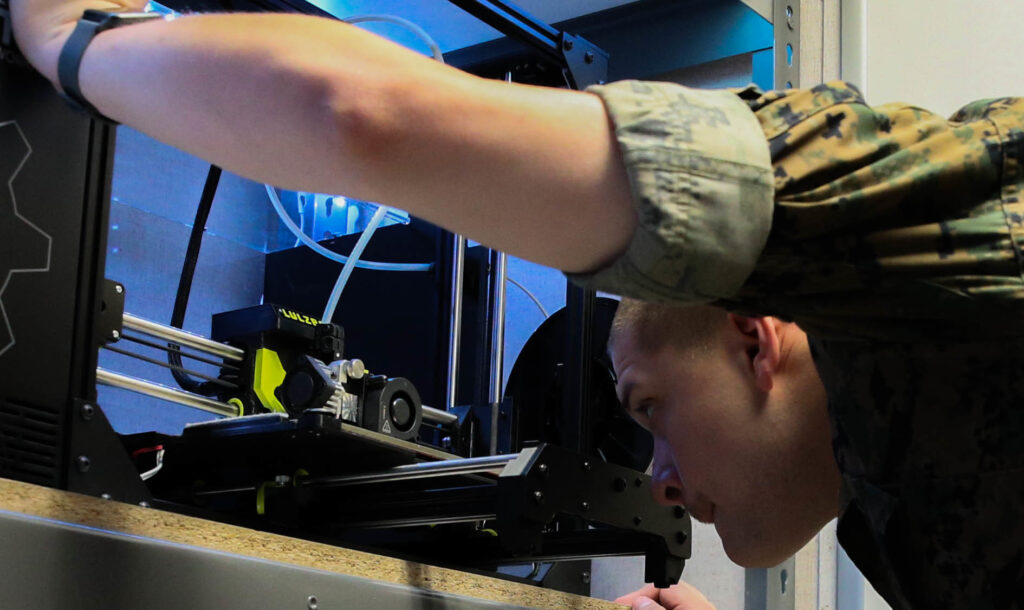

The US military is examining 3D printing technology as a solution for frontline equipment repairs. During a recent congressional hearing on military spending, Chairman of the Joint Chiefs Gen. Dan Caine stated that “the force of the future will fix on the spot.” This approach aims to reduce the practice of cannibalization, where parts are harvested from some equipment to repair others.

Logistics challenges are particularly significant in potential Pacific conflicts, where vast distances between island chains create supply difficulties. The Department of Defense is exploring options for troops to produce necessary parts directly at forward positions without access to established maintenance facilities. This capability could be critical in scenarios where traditional supply chains are disrupted or impractical.

“I’m really encouraged by the innovation that’s happening to look at things like additive manufacturing, where we get a hold of the specs from companies like Lockheed and others,” Caine said, “and can just 3D print right on the spot the requirement.” The military has been testing 3D printing technology for years, including recent concrete-based printing projects at Fort Bliss, Texas.

Similar applications are already appearing in conflict zones worldwide. In Myanmar, rebel fighters have used 3D printers to manufacture weapons parts, while Ukrainian forces have printed components for improvised devices. These real-world implementations demonstrate the technology’s potential utility in combat situations.

The effectiveness of battlefield 3D printing will ultimately depend on practical considerations like speed and portability. Current industrial 3D printing processes can take days to complete, which may not be feasible in combat scenarios. If the equipment proves too slow or cumbersome, troops might revert to traditional repair methods despite the technological potential.

Source: businessinsider.nl