Researchers at Virginia Tech have developed a method to create shape-memory ceramic materials that can be manufactured at scale using 3D printing technology. Associate professor Hang Yu, along with Ph.D. student Donnie Erb and postdoctoral researcher Nikhil Gotawala, used additive friction stir deposition to embed ceramic particles into metal matrices. Their research was published in Materials Science and Engineering R: Reports.

The team’s approach addresses a long-standing challenge in materials science. Shape-memory ceramics can change their internal structure under stress or heat and return to their original form, but they have historically been too brittle for large-scale manufacturing. Previous research showed these materials worked at microscale, but scaling up for structural applications proved difficult as the materials would break apart.

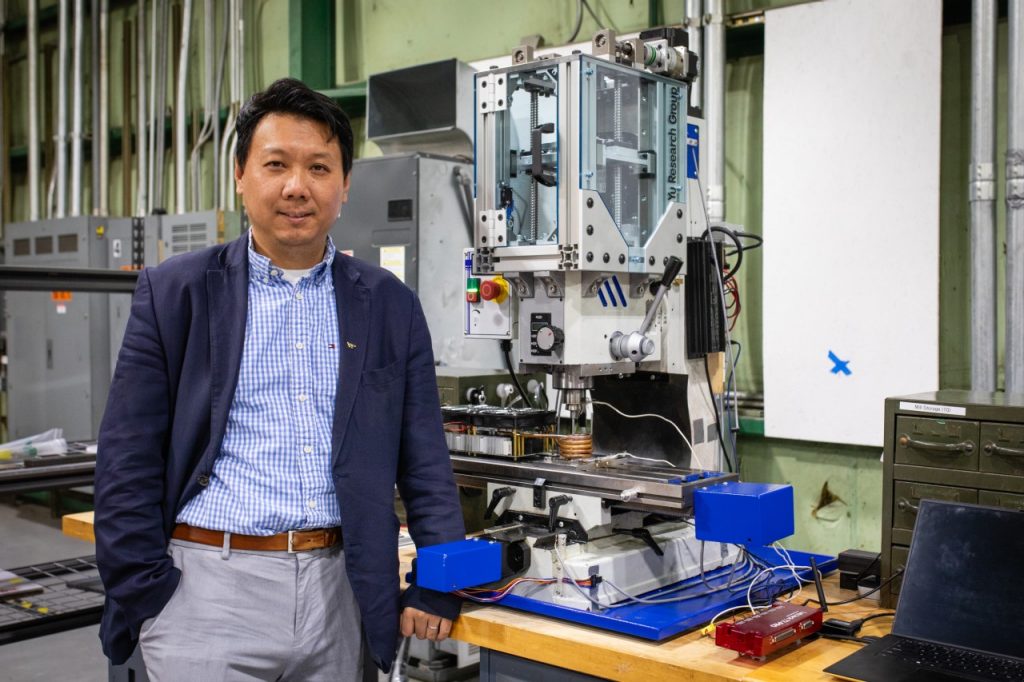

The new technique embeds tiny shape-memory ceramic particles into metal using a process Yu compared to “putting chocolate chips into cookie dough.” The additive friction stir deposition machine spins the materials fast enough to meld them together without melting, creating a composite that maintains the ceramic’s shape-memory properties while gaining the metal’s structural integrity. “This composite can afford tension, bending, compression, and absorb energy through stress-induced martensitic transformation,” said Yu.

The resulting material could have applications in defense systems, aerospace, infrastructure, and sporting equipment. Potential uses include vibration damping in golf club shafts or impact absorption in defense applications. “For the first time, this research creates bulk shape-memory ceramic–metal matrix composites using a scalable, solid-state 3D-printing process,” Yu said. The research was supported by the National Science Foundation and the U.S. Army Research Laboratory.

Source: news.vt.edu