Berlin-based Xolo has raised €8 million in a series A funding round to develop its next-generation 3D printing technology, known as xolography.

Unlike traditional 3D printing methods, which rely on layerwise deposition across a flat plane, “xolography” uses volumetric 3D measurements to estimate printing output using light.

This allows for smoother and more complex components to be produced with greater speed, making the technology well-suited for industries like bioprinting, dentistry, and acoustics.

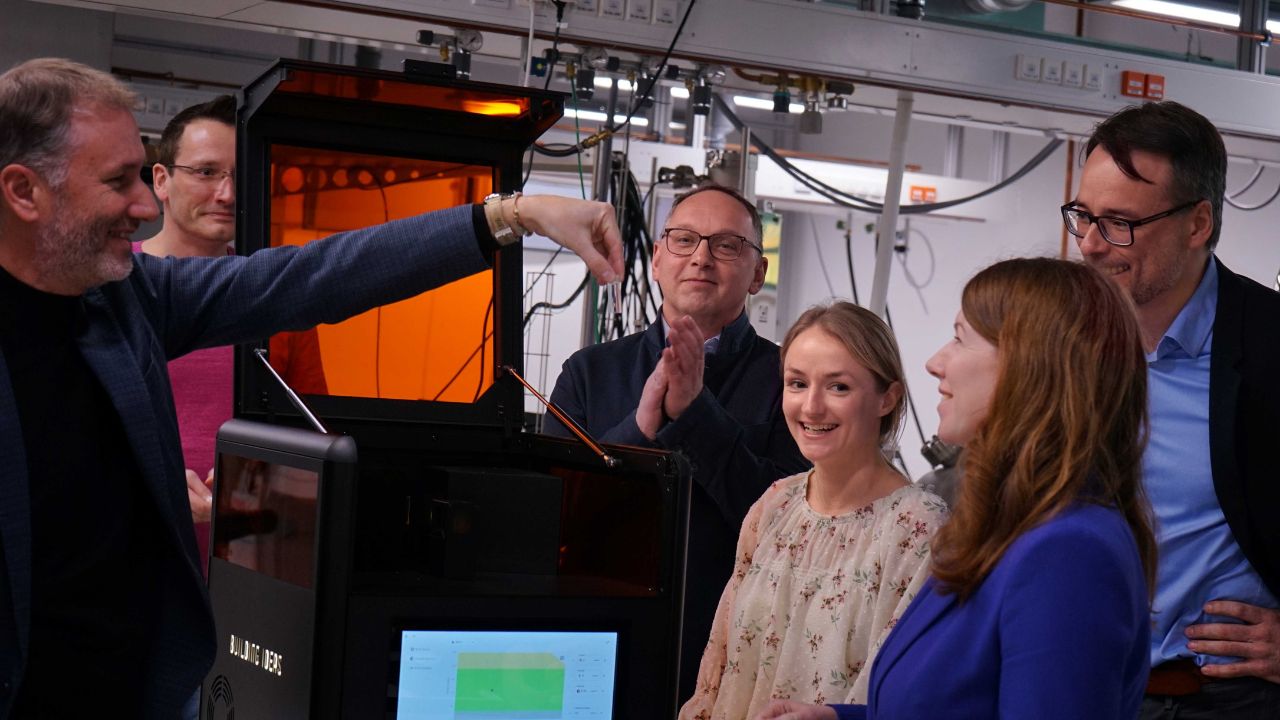

The company’s Xube 3D printer uses a cuvette with liquid resin that is continuously absorbed via a light sheet and enhanced with photoactive specialty chemicals to create smooth surfaces in a short amount of time.

The technology has already attracted interest from research and development teams in the optics and biomaterials industries.

“Xolography represents a fundamental shift in the 3D printing industry,” said Dirk Radzinski, Xolo co-founder and CEO.

“From hardware to materials, everything is being rethought. Our investors understand the importance of this paradigm shift and support us with their financial strength, expertise and network towards making it a success.”

Funded

The funding round was led by DeepTech & Climate Fonds and HZG Group, along with Kerstin and Frank Carsten Herzog, Onsight Ventures, and existing investor SquareOne. Xolo’s technology could represent a major breakthrough in the 3D printing industry, unlocking new possibilities for high-speed, high-precision manufacturing.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.