A 3D print is no better than its design. Hardware in 3D printers has improved to the point that it’s now rarely the bottleneck of performance. More often, the shape of a part is the limiting factor of its performance. As such, there’s been a lot of discussion and research as of late into designing for additive manufacturing (DFAM). We recently covered the design guidelines for the different 3D printing technologies, and that’s an important starting point for DFAM but it doesn’t include the full picture. While those guidelines are concerned with the limits of 3D printing, the other component of DFAM is considering all of the possibilities enabled by 3D printing.

There are three main principles that make up DFAM, though there’s a lot of overlap between them and some objects will include aspects of all of them. Those principles are part consolidation of assemblies and sub-assemblies, geometric freedom, and biomimicry.

Part Consolidation

Multiple benefits come with reducing the number of parts in an assembly. Reduced complexity speeds up production and lowers costs, especially if the various parts are produced by different companies using different manufacturing technologies. Consolidated assemblies also exhibit increased durability due to having fewer seams and tighter tolerances, and reduced part interfaces means less vibration and fewer paths for leaks. There’s also usually a weight reduction that comes with consolidation due to not having to use fasteners like nuts and bolts to hold everything together.

With 3D printing, part consolidation can reduce assemblies from hundreds of part to just a few. Industries are currently going through a period of redesigning assemblies, originally designed to be produced using traditional manufacturing techniques, into more consolidated forms that are 3D printable. DFAM is most efficient when it’s applied from the very beginning of a part’s design but there are still gains to be had by applying it to existing parts.

One of the best examples of part consolidation with 3D printing is GE’s Catalyst Advanced Turboprop engine, which was reduced from a whopping 852 parts to a mere 12; the bearing and sump assemblies were reduced from 80 parts to 1! And that’s with 3D printing only a quarter of the parts. The new design burns 1% less fuel and weighs 5% less, significant improvements for an engine made for planes.

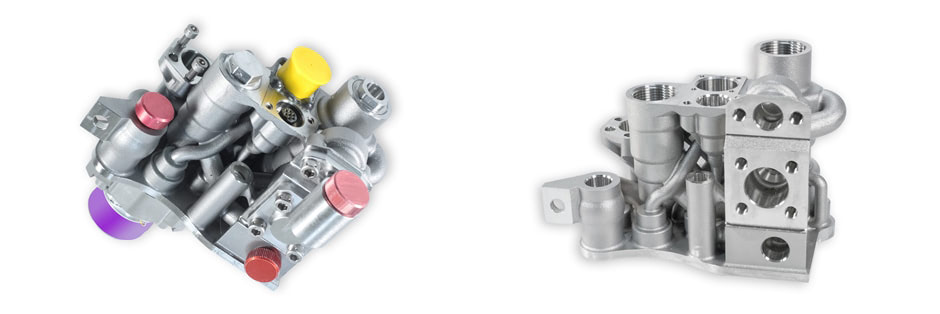

Airbus has also used 3D printing to consolidate parts for planes. They consolidated a hydraulic component from 10 parts to 1, reducing its weight by 35%. A complex system of pipework with lots of transverse bores was entirely eliminated, making the component easier to service. The component was successfully trialed in a test flight on the A380.

Geometric Freedom

Having the freedom to make a part in the shape that best serves its purpose is a unique advantage to 3D printing. Traditional manufacturing methods box designers and engineers into geometries that are easy to fabricate, such as the hard angles and circular holes produced by CNC machines. If the ideal shape that results in the strongest part can’t be manufactured, engineers have to compensate with extra material or risk producing a weak part. This usually means parts are over-engineered with excess material because it’s better to use a little too much material than to have a part fail.

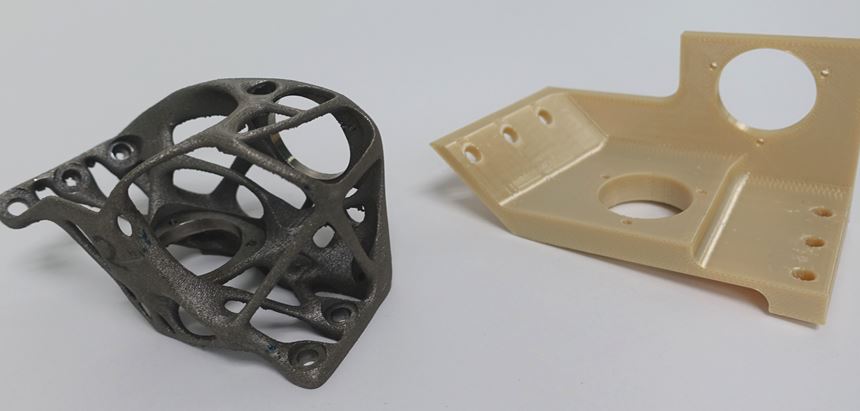

When people say “complexity is free in 3D printing,” this is what they’re referring to. For the most part, it doesn’t cost more to produce a more complex shape in 3D printing. When engineers are free to determine the shape of components, the components will have fewer stress points, smaller footprints, and superior mechanical properties. Additionally, they can employ generative design and topology optimization tools. Such tools allow engineers to set part parameters like mount points and environmental stresses without dictating the exact shape of the object; geometries are generated by AI and run through a series of simulations to decide the optimal design. Parts generated this way are aesthetically very different from traditionally-manufactured parts, featuring sweeping arches and irregular voids that can only be produced with AM.

GM and Autodesk used generative design tools in Fusion360 to create a car seat mount that reduced the assembly from eight parts to one; it weighs 40% less and is 20% stronger.

This bracket for the U.S. Army Aviation and Missile Research Development and Engineering Center (AMRDEC) was also generated with topology optimization and is significantly stiffer than the original part.

Biomimicry

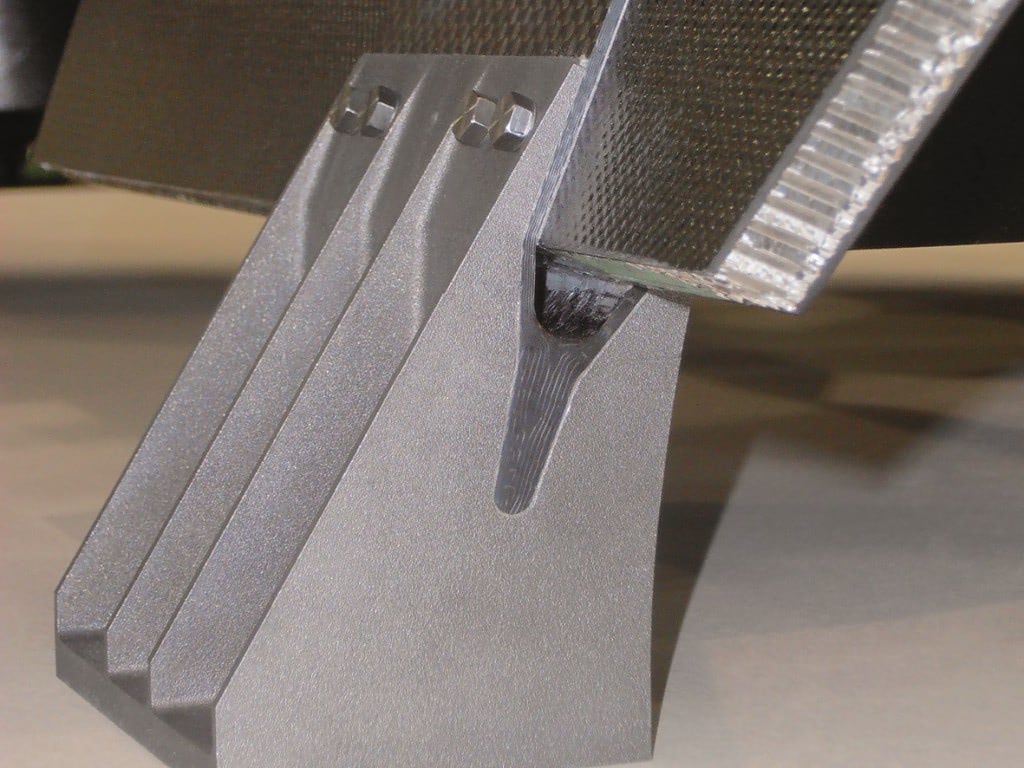

Biomimicry is the concept of improving functionality by incorporating elements of biological systems because nature has had a few billion years to specialize certain functions thanks to the process of evolution. One of the best examples of this is the airplane, the wings of which are shaped and designed to flex just like the wings of birds. 3D printing empowers designers to model solutions based on the organic systems found in nature, which are generally difficult to produce with traditional manufacturing. Even the triangular and honeycomb infill patterns found in many FDM prints could be attributed to biomimicry as those patterns are found in plant-cell structures.

Ongoing efforts to 3D print bone are partly driven by the desire to harness the internal structure that lends bone its flexibility and high strength-to-weight ratio. In fact, Airbus is 3D printing partitions that are modeled after bone.

Researchers at Northeastern University College of Engineering are finding inspiration from the scales of fish to 3D print body armor. For their project, geometry and flexibility were equally important so 3D printing was their only manufacturing option.

Whether engineers are trying to reduce parts, improve performance, or increase functionality, they use the principles of DFAM to optimize the overall efficiency of fabricating parts with AM.

You can contact us now for a company scan or product scan. We can find out exactly how and where your company is likely to benefit from implementing DFAM.