Granule / pellet printing is the way forward, as most of you will probably agree.

Also known as Fused Granular Fabrication (FGF), it is already the standard for industrial printing and for large format printing for a variety of reasons, cost being one such reason, which we will discuss later.

However, it has not really reached the hobbyist / prosumer level yet, largely due to the cost of the granule extruder system. Currently, a decent granule extruder / hotend is going to cost around $10,000 just for the hotend. If you want the motion system and structure, it’s going to cost you extra.

What we really need is a mass produced all-in-one solution to drive down the barrier to entry.

Piocreat 3D G5 – Cost Effective Pellet Printing

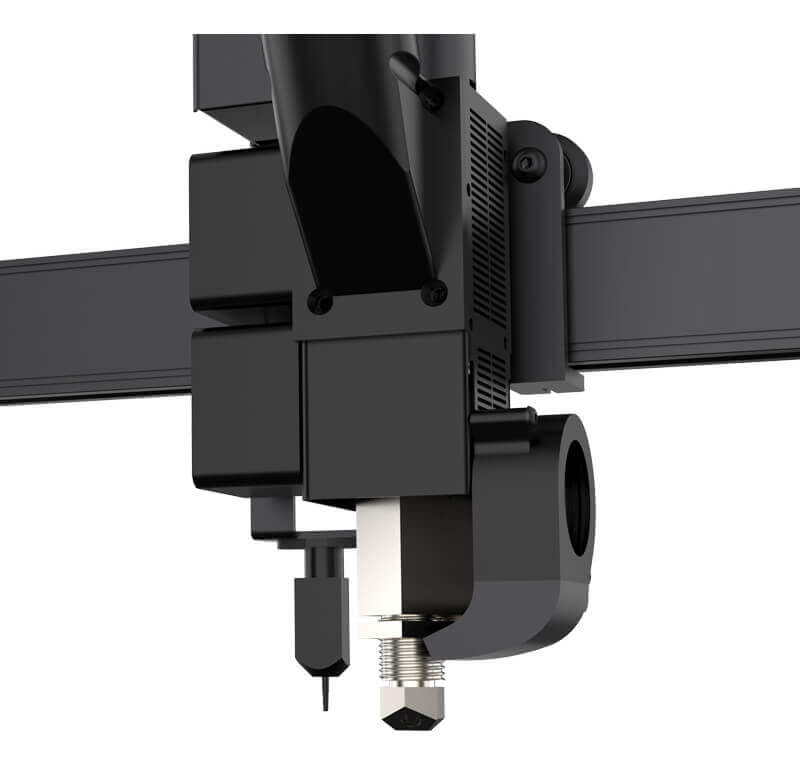

Shenzhen-based Piocreat 3D is attempting to do just that. They are hoping to bring granular thermoplastic printing to the masses with their G5 printer, which includes the structure, control system, electronics, hotend/extruder and a hopper.

You can see the Piocreat 3D G5 in the image below.

The Piocreat 3D G5 features a build volume of an impressive 500mm x 500mm x 500mm, dual Z-axis lead screws with dual tie rods and a rapidly heating bed capable of hitting 60°C in just over 2 minutes, which is not bad for a print bed of that size. The printer bed can reach a maximum of 150°C, which helps in reducing warpage on high temperature engineering plastics.

The granules are fed from the hopper into the screw-type extruder system where it is extruded via nozzles from 0.8mm up to 2mm in diameter, which when combined with over 100mm/s print speed allows for deposition rates of up to 200 grams per hour. The G5 is capable of printing at layer heights of 0.2 up to 1mm.

You can use a variety of pellets in the G5 including PLA, ABS, polycarbonate, HDPE and more. Just remember, this printer is not enclosed, so you may wish to erect an enclosure of your own when dealing with certain warp-prone plastics.

Why Use FGF?

Your common FDM filament starts as a granulate before it is fed into the extruders and cooling systems to take its final form as filament feedstock. Then it must be wound onto a reel and stored in bulk, which takes up warehouse space.

And that’s not to mention the waste generated from the plastic spools themselves. With granules, you don’t pay for the storage space, or the economical cost of manufacturing, transporting and disposing of empty spools. Granules are simply better for the environment compared to filaments.

All of these additional manufacturing steps and storage/transportation stages add cost to filament production, and that not insignificant cost is passed on to the customer.

You can buy thermoplastic granules for 10x less cost than the equivalent filament in many cases, so the question remains, why even bother with filament in the first place?

Why indeed. It’s time to move away from filament, and the G5 seems to be a good way to do this for those looking for a low barrier to entry into granule printing.

The Piocreat 3D G5 is on sale now retailing for $3999 USD, therefore making industrial pellet printing accessible to SMEs, small workshops, universities and serious hobbyists alike.

For more information on the G5 FGF printer, you can head on over to the Piocreat 3D website at this link.