3D Printing flexible filament on a desktop 3D printer can be a bit tricky. Slicer software settings and 3D printer hardware both come into play when trying to get a successful print.

Slicer software settings

Mainly, print speed and retraction are the slicer software settings you need to get right. Our advice is to print really slow and to turn off retraction. Constant retracting and extruding can cause under-extrusion.

3D printer hardware

The build surface and extruder type of your 3D printer are also important. When printing on a cold print bed make sure to use some sort of adhesive layer. In case your printer has a heated bed with a glass surface there’s a fair chance you don’t need an extra adhesive layer.

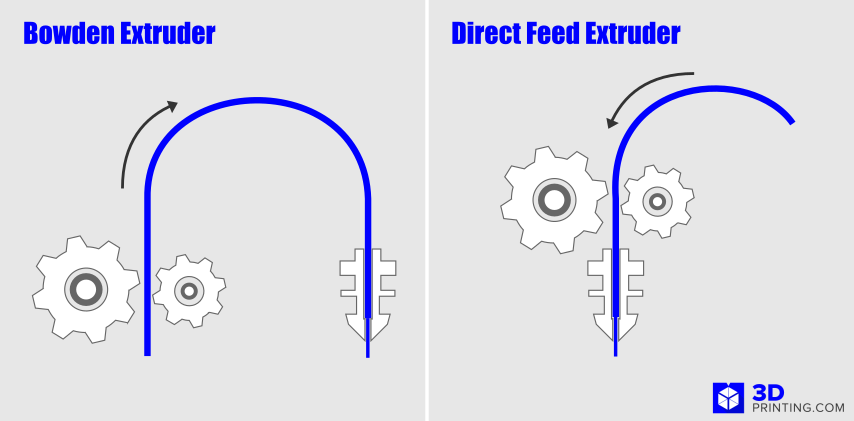

Bowden versus Direct Extruder

A few years ago it was basically impossible to print flexible 3D printer filament with a bowden extruder. However, times have changed and extruders have improved a lot. Nowadays you have a good chance your bowden extruder is also up to the task.

Direct extruders are placed on top of the moving parts of a 3D printer. The weight of the stepper motor slows down the travel and print speeds. When you print at high speed with a direct extruder, the print quality might decrease.

Bowden printers on the other hand can achieve better print quality, while printing at high speed.

Fully Constrained Filament Path

The most important element which decides if your printer is up to the task of printing flexible filament is the way it constrains the filament path. A fully constrained path from the idler/gear pinch point to the hot end means there is nowhere for the filament to escape or get stuck.

A good example of an extruder with a fully constrained filament path is the Bondtech QR. It can be configured either as a direct or bowden setup.