Last week we took a look at the 3D printed liquid rocket engine in the world from a Brooklyn-based company called Launcher. They had 3D printed a copper rocket nozzle, throat and combustion chamber and had performed many tests on the engine. It will have test flights later in the year.

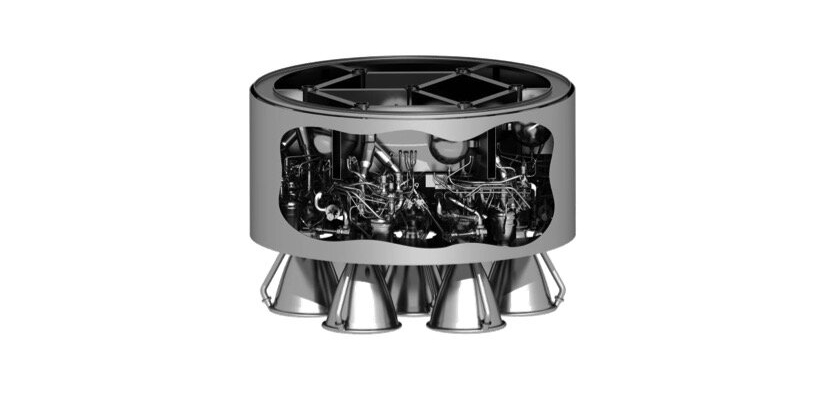

ESA are also looking at ways of 3D printing their own rocket engine as part of their Prometheus engine project, and they have posted a few pictures of some components on their blog last week. The image below shows a rendering of a cluster of the Prometheus engines in some particular upper-stage configuration.

Prometheus is the European effort to keep the European launch industry competitive in the face of companies such as SpaceX, who have annoyed everybody by making rockets that you don’t throw away after a single use.

The developers of the next generation European rocket, the Ariane 6, were likely not counting on competing with fully reusable rockets when they initially carved out the business case.

But now that they have to compete, they are pulling out all the stops to ensure that the next gen of European launchers are as economically efficient as possible. That’s not just in terms of performance, but in the manufacturing too.

And so that’s why we are here, talking about ESA and their 3D printed engine. Or as ESA likes to call it, ALM (Additive Layered Manufacturing).

Presumably, ESA doesn’t want us getting confused with other non-layered forms of additive manufacturing, such as clay forming or basket weaving.

The Prometheus engine is basically a test bed intended to bring the technology up to a level of maturity where it can be used in industry. Possible uses for the engine could be in the future European Ariane 6 launcher. It is hoped that by using lessons from the Prometheus precursor project, Ariane Group will be able to reduce the cost of manufacturing the new engines by ten times, compared to today’s current Ariane 5 engine.

Reusability is a key component of Prometheus. While the ESA does not have a reusable launcher, they have been experimenting with various fly-back technologies as part of their future launcher preparatory roadmap (of which Prometheus is also a part).

So Prometheus is being designed with as much flexibility as possible, so it can not only fit on future evolutions of the Ariane 6, but also any future usable launchers that ESA/Ariane Group may develop.

3D Printed Parts

So, now you know why…let’s have a look at what is being printed…or ALM’ed on Prometheus.

According to ESA’s blog, Prometheus has a 3D printed thrust chamber (nozzle, throat, combustion chamber and injector face), a bunch of AM valves, and an AM gas generator (so far). That’s quite a large percentage of engine.

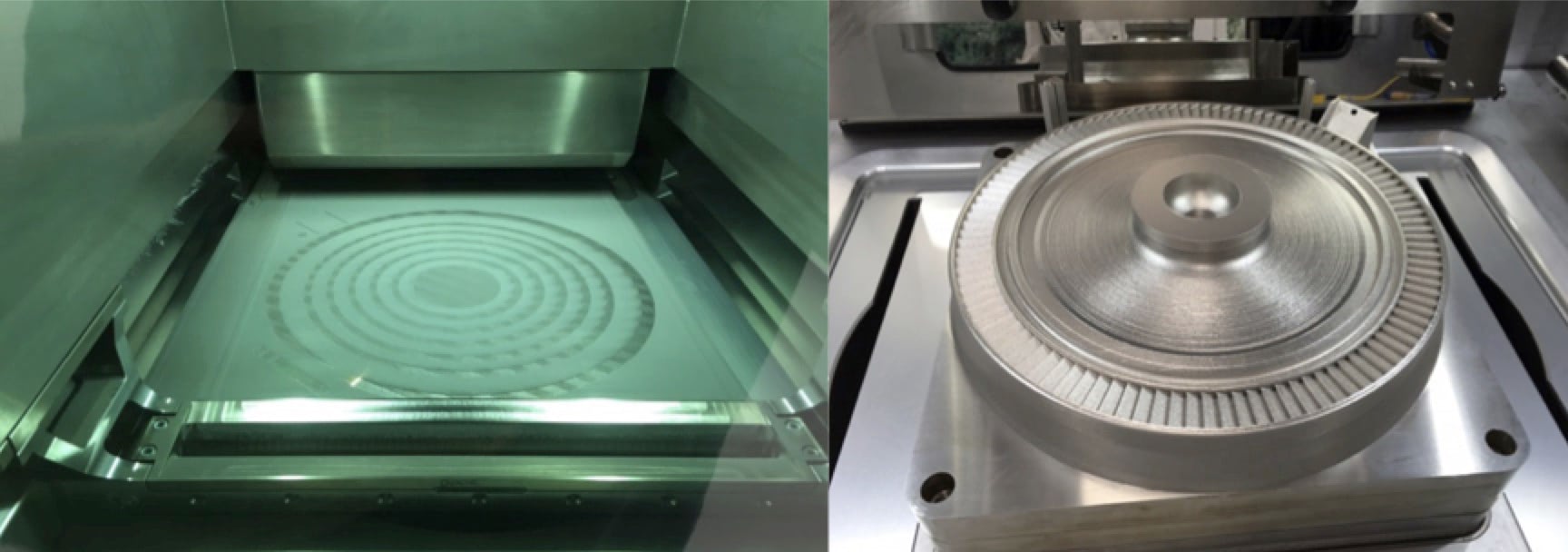

Various turbomachinery components have also been manufactured with some form of powder bed fusion process, as you can see in the image below.

In the picture below, you can see the Prometheus gas generator being tested.

It is not known if the gas generator is fully 3D printed, but it was shown in a paper presented at the EUCASS conference in 2019 that they are aiming for a full 3D printed gas generator, and basically a fully 3D printed engine is the aim.

According to ESA, “redesign of industrialization schemes based on extensive use of ALM process is indeed one of the key to achieve the 1 million EUR production cost.”

The 1 million EUR cost is one tenth the manufacturing cost for the current engines.

And according to the aforementioned paper, the agency isn’t too far off achieving that, largely due to the existence of the capabilities existing in ESA already.

With recent hotfire tests of the thrust chamber complete, the ESA is a step closer to having reusable engines…even if they don’t have reusable rockets. Yet.

Engineers will assemble the full-scale Prometheus demonstrator (named as “M1”) at the end of this year, with testing on the ground scheduled for 2021.