As anyone who has ever touched a 3D printer knows by now, many different additive manufacturing processes result in anisotropy of the part. That is to say, the part’s strength varies along the different axes, usually due to the interlayer bonding sections having less strength than the bonded molecules in the layer itself.

This is a pain for a variety of reasons, largely focused on part orientation as it is being printed, and also in its final usage. Naturally, with an isotropic part, you can use it in real life knowing that it’s not going to break if you look at it the wrong way.

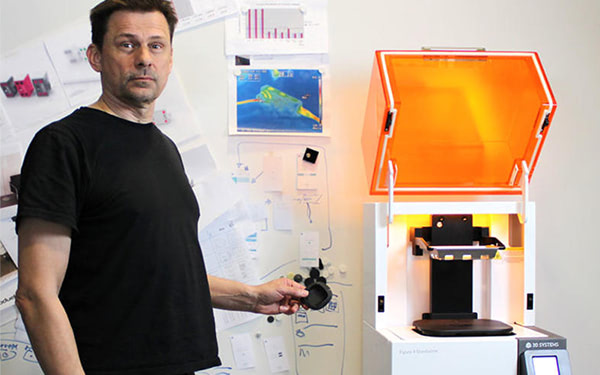

Well, 3D Systems has you covered if you are craving some isotropy in your lives. And they have even made a video to remind you of why you need it.

“Figure 4 parts have isotropic properties. We’ve done the testing and documented the results, and this is a big deal for throughput because part orientation doesn’t change part strength, enabling far greater capacity,” said Marty Johnson, Technical Fellow at 3D Systems.

Yes, the isotropic-ness of a part apparently directly affects the throughput of a production line. How?

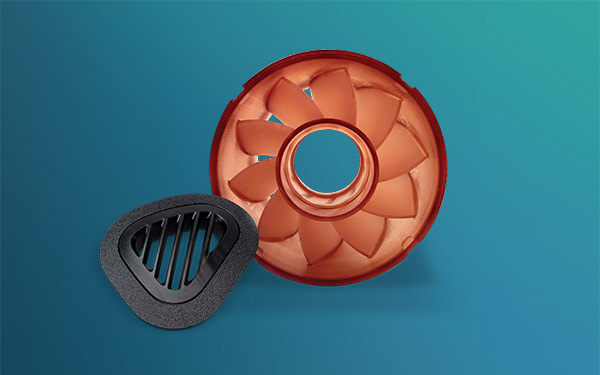

If you are printing with a more traditional 3D printing method with anisotropic results, then your print job must first be oriented so that the part functions as designed, then you must orient it to maximise space on the printer (if printing in production level volumes).. these are all incredibly restrictive factors when it comes to designing a nice product, and designing it so its manufacturing has been optimised, economically speaking.

If build orientation no longer affects strength, then your design freedom increases significantly. You can print it in any orientation, it will work the same in any direction (all things being equal). You can now print many of the same parts in one go, but oriented in different directions on the same build plate, and make the most of that area. It makes no difference to the strength of the final part.

It seems that seemingly small details like the isotropic-ness of parts which we take for granted as 3D printing fans can have effects further downstream. Food for thought.

White Paper: Significant Cost Savings Over Cast Urethane

White Paper: Significant Cost Savings Over Cast Urethane

Figure 4 Standalone Customer Story

Figure 4 Standalone Customer Story

White Paper: A Digital Alternative to Injection Molding

White Paper: A Digital Alternative to Injection Molding