Earlier this year 3D Systems announced that they would be stepping up their efforts in the realm of bioprinting, in particular they intend to collaborate further with United Therapeutics and their subsidiary Lung Biotechnology, for the manufacture of printed organ scaffolds.

So what are the details of this enhanced collaboration and what does it mean for the future of 3D printed organs? Read on to know more about their development plans for engineered lungs.

Collaboration

3D Systems has been working with United Therapeutics for a while and much of their work has been focused on the development of printer systems and processes for organ scaffolds. It would seem that the main platform being used here has been the 3D Systems Figure 4 system in combination with various proprietary bioinks.

In 2020 it was announced that the companies had successfully demonstrated high rate, micron-level printing, which is required for vascularization (needed to sustain living cells). In addition, they had made significant developments in material formulation using a unique rhCollagen.

These big steps forward have led to the increased commitment to the research, as announced earlier this year.

With the further investment the partners will develop these processes further.

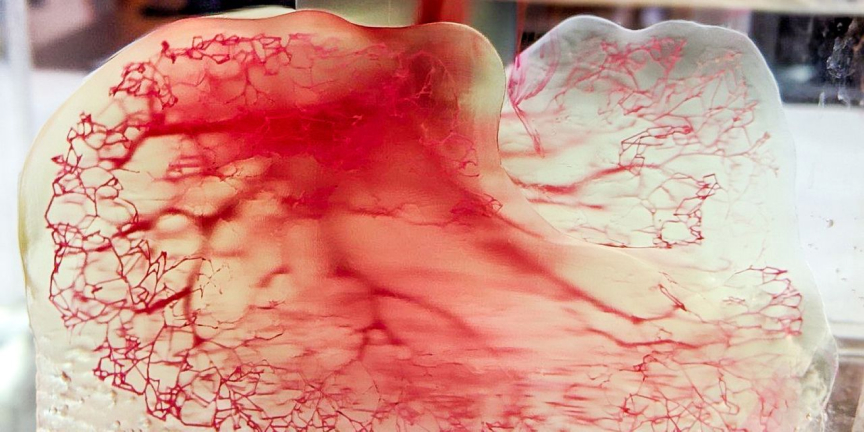

The research will help open up opportunities in regenerative medicine, including the development of non-solid organ applications requiring biologically sustainable vasculature (blood vessels). You can see an example of the printed blood vessels in the image below.

Print to Perfusion

This research has culminated in the Print to Perfusion process.

This involves using the custom materials and optimized process to rapidly create high-resolution hydrogel scaffolds which can be perfused with living cells to create tissues.

“We put a team together between the two companies,” said Chuck Hull, CTO of 3D Systems, in an interview with Forbes.

“There was a lot to work out. We decided to print the scaffolds with hydrogels, because the body is mostly water, but that meant printing a material that’s gooey and soft. We’re used to printing in hard plastics. Once we got that figured out, then we knew the cells needed someplace to grow. That meant printing in fine detail to allow spaces for cells to live in. But printing smaller, with high resolution, slows things down, so then we needed higher print speeds.

Those things have taken the last three years to figure out, and there’s still clinical trials and regulatory work to be done—but on the technology side of the scaffolds themselves, I’d say we could implement that now.”

United Therapeutics has a “pipeline of development” on their website, showing milestones they hope to achieve with this process.

They plan to start by developing technologies such as inhalation devices for Trepostinil (for the relief of Pulmonary arterial hypertension) in the short term. The manufactured organs will presumably aid with this path of drug discovery.

Medium term, they say they will be developing other inhalation technologies for treatment of lung diseases and move into the manufacture of xeno-organs (made from pig organ scaffolds) such as the xeno-kidney, xeno-heart and uni-lung.

The long term goal is clearly to engineer a pair of transplantable lungs for use in late stage lung disease patients, with a printed scaffold and perfused with either allogeneic cells or cells from the patient.

Will it really be so simple? Click on a link and buy a new set of 3D Printed lungs?

We may have to wait a while for the tech to mature and get certified for use in humans. But for now, it seems like there is a clear route emerging.