Wax casting is perhaps the most ancient of manufacturing methods to have been augmented by 3D printing, and the innovations don’t seem to be slowing down much, as 3D Systems has just announced the release of their VisiJet Wax Jewel Red Material.

What is VisiJet? Read on to know more.

Wax Casting

We have covered wax casting in this previous article, but just by means of a reminder, the process involves making a wax duplicate of the item being manufactured, which is then dipped into a refractory slurry. The slurryfied wax piece then dries, and the wax can be removed with heat, leaving an exact negative of the wax piece (and therefore the original piece) at a cavity in the mold. Molten metal is then poured into the dried slurry mold, and it takes the form of the cavity. In ancient times, the wax pattern was often made by hand, and was incredibly time consuming.

Naturally, 3D printing has reduced the labor involved in this process by simply printing a wax pattern, perfectly emulating the design produced in the CAD software.

Casting with wax is a great way of creating intricate parts with excellent surface finishes, and this is why it has been used in so many industries ranging from aerospace (for turbine blades) to dentistry to jewelry. And that’s where the new VisiJet Wax Jewel Red material comes in…

Wax can be a little bit weak and can break easily, especially when being manhandled at various stages of a lost wax production process.

VisiJet Wax Jewel Red

The new VisiJet Wax Jewel Red material from 3D Systems has been designed with extra durability and flexibility in mind, which will undoubtedly be good news for jewelers who have already integrated AM into their workflows.

The new material is made from 100% wax, has increased durability and flexibility, and comes in high contrast red color for visibility.

As it is completely compatible with existing wax casting workflows, the new VisiJet material can be used without deviating from usual practices. Of course, you still need a 3D Systems printer capable of printing wax, such as the MJP series of printers, but we digress…

The wax provides a clean burnout when removing the wax, and leaves no ash in its place.

The improved durability and flexibility enables a whole new degree of detail in jewelry making, including the ability to cast fine mesh and filigree design jewelry castings. Of course, traditional jewellery designs are still possible, as are stone-in-place castings.

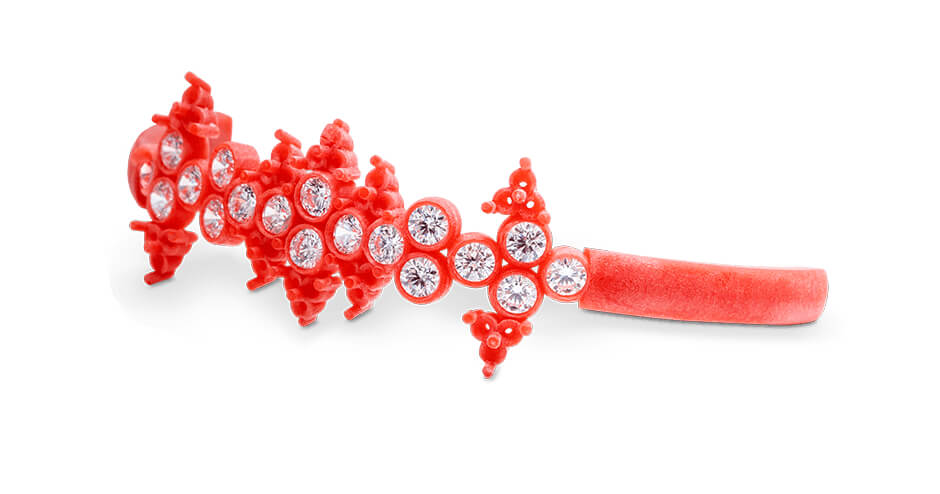

A stone-in-place casting is when the stones are placed into the wax, and are embedded into the slurry when the wax is dipped. As the slurry dries, the stones are held in place, even when the wax is melted out. When the molten metal is poured into the investment, it anchors onto the stones (or the stone fasteners) so that they are embedded into the jewelry. This method can be used on a variety of gems including cubic zirconia, sapphire, ruby, garnet and diamond (and more).

You can see an example of stones embedded in the red wax in the picture below.

“Additive manufacturing has made its mark on the jewelry industry – allowing artisans to push the boundaries and take their creativity to new levels,” said Dr. Edwin Hortelano, senior vice president, materials engineering & development, 3D Systems.

“We created VisiJet Wax Jewel Red as the next step in our 100% wax casting portfolio, specifically to enable the unmatched quality of lost wax casting for jewelry design styles with fine features. This addition helps artisans and casting houses deliver unique designs while improving productivity and reducing costs.”

If you would like to know more about wax casting with AM patterns, you can read the free ebook from 3D Systems.