3D printing complex shapes or hollow parts can sometimes be problematic. What if you could print them flat and fold the part to the desired configuration? This requires a combination of the right material, design and print strategy. When done properly, the results are highly useful.

The Right Material for 3D Printing Living Hinges

Fortunately, Nylon is an ideal 3D printing material for such applications. Its combination of high mechanical strength and resilience make it the ideal material for 3D printing living hinges. This material will not crack when bent, and these printed hinges will not wear out, even after constant flexing.

The Right Design

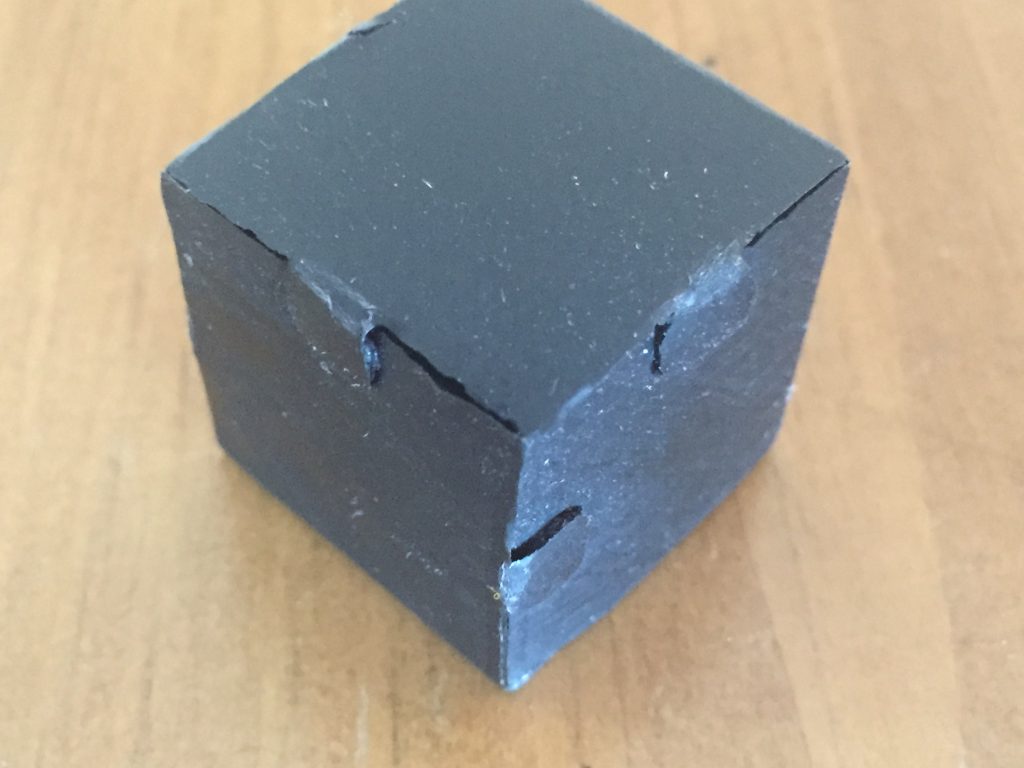

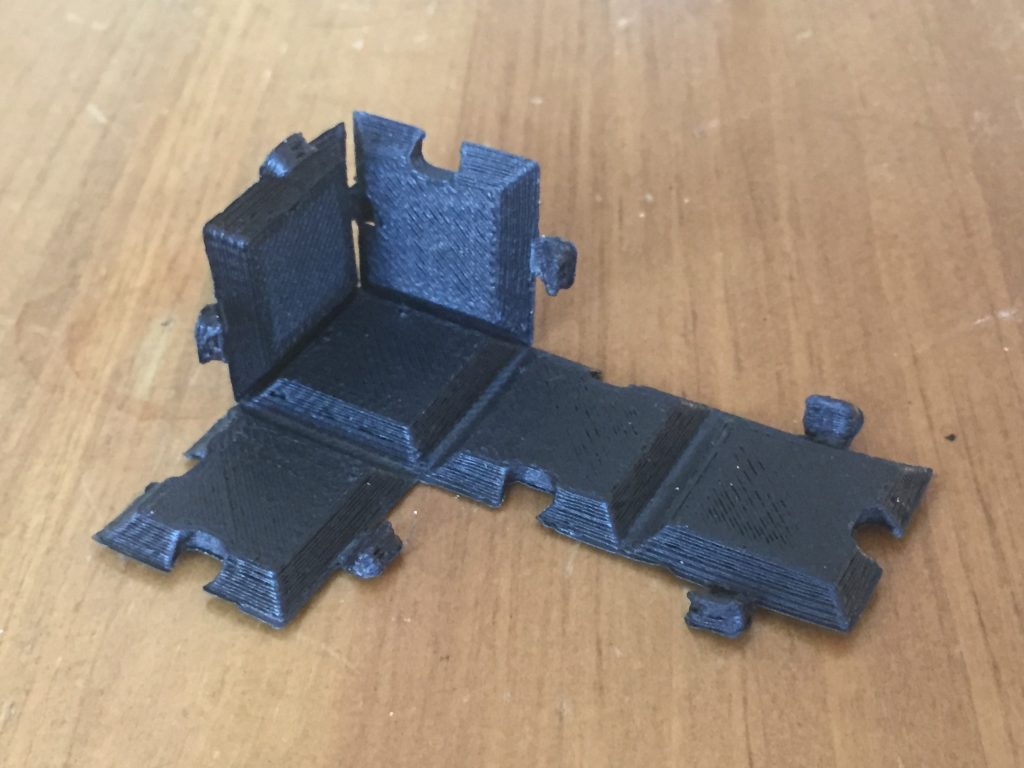

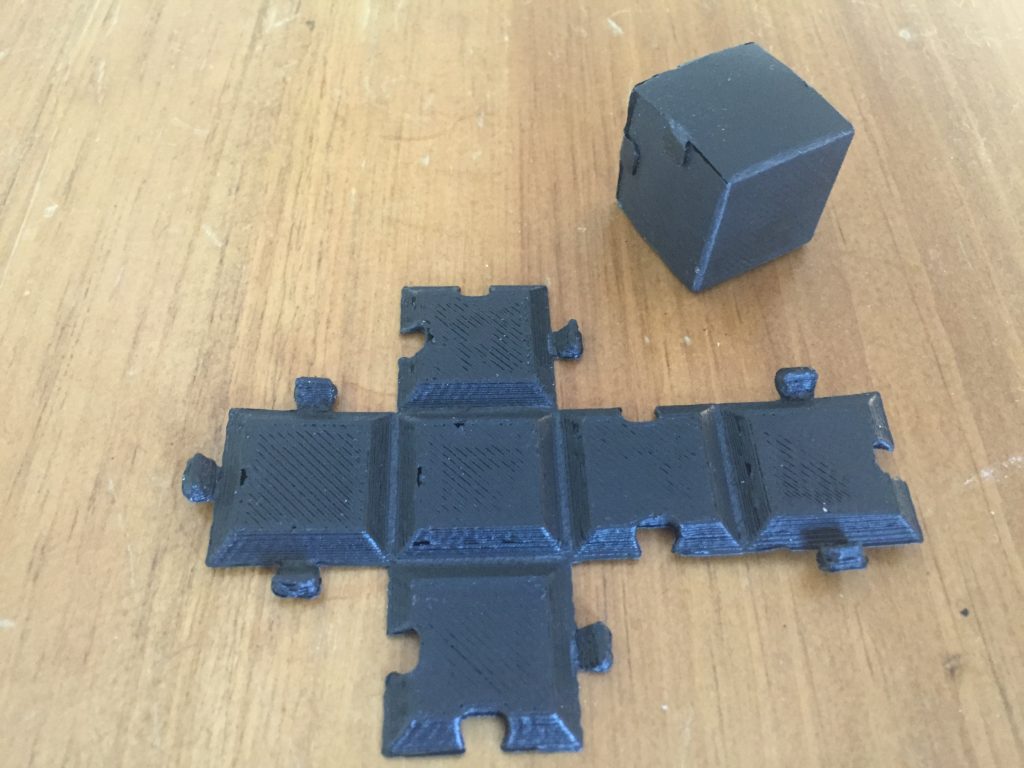

This cube shaped box is assembled by folding each segment and press fitting the tabs into the adjacent side wall. By designing in V shaped notches between sections the walls fold neatly with minimum stress. The thin hinge bends and holds in place.

The hinged connecting tabs have been designed to fit snugly into the corresponding female notches. Press fit the hinged tabs into the notches and there is sufficient pressure to keep the tabs in place, even when under mechanical loading.

The hinges were designed to be two solid layers thick, providing for a balance of flexibility and strength. This design utilizes the characteristics of the material to create a stable and mechanically strong box.

The Right Print Strategy

3D Print strategy provides for mechanical strength where needed and flexibility where appropriate. In this example, the part was printed with a single outer layer and 25% infill. This implements the appropriate balance of strength and flexibility: the walls are stiff but the hinges flex sufficiently to allow for stable 90º bends. The two layer tab hinges provide the flexibility to press fit the tabs in place without sacrificing strength.

Make Complex Working Parts that Flex

Proper use of hinges greatly expands your ability to make useful, complex parts that will hold up under use.