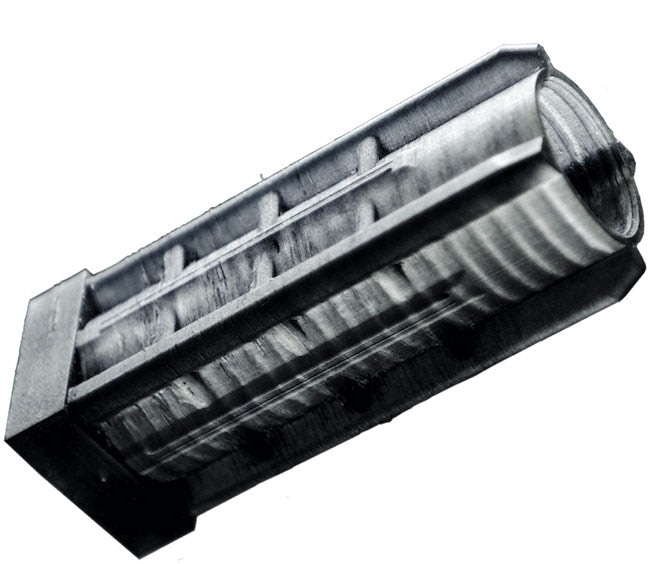

Fortify, a Digital Composite Manufacturing (DCM) firm in Boston, and DSM, a Dutch multinational chemical company, have partnered up to develop industrial-grade composite materials for 3D printing end-use parts and structural components. The companies will develop the materials using Fortify’s DCM platform, which is powered by Fluxprint technology where magnets are integrated into DLP 3D printing to align fiber reinforcements in 3D prints during the printing process.

DSM also backed the seed funding that launched the Fortify Fiber Platform that invites industrial partners to join Fortify’s material scientists and engineers to create new composites to meet the demanding requirements of critical applications. Hugo da Silva, VP of Additive Manufacturing at DSM, commented on the partnership: “Partnering with Fortify allows us to develop high-performance composite materials for DLP technology, making the technology viable for functional parts and demanding applications.”

DSM already produces many high-quality resins, so they’re uniquely positioned to work with Fortify’s Fiber Platform to increase the mechanical properties of those resins. Fortify will also sell DSM materials through its DCM platform, expanding their materials catalogue. “DSM is an ideal partner for us,” said Josh Martin, CEO of Fortify. “Our collaboration allows us to leverage DSM’s mature supply chain and years of experience developing advanced materials to expand our resin palette. We’re excited to partner with an industry leader and work with them to develop cutting-edge resins.”

As a chemical company, DSM has served the nutrition, health, and materials markets for over a century. They produce materials for various forms of manufacturing, not just 3D printing, so they bring along copious amounts of multidisciplinary experience with them to all of their partnerships, of which there are many. Just within 3D printing, they develop and produce materials for FFF, SLS, SLA, ink jet, and binder jet processes. They have partnerships with Formfutura (to distribute their filament) and Ultimaker (where they develop filaments and create slicing software profiles), among others.

Fortify’s patented Fluxprint technology will have a large impact on the collaboration as the resins will need to be optimized to accommodate the precise magnetic positioning of the fiber reinforcements. Their ceramic reinforcements will likely also be included in the developments. The composites that come out of this collaboration will replace metals in some applications, and engineers around the world will reap the benefits.