Metal powders are costly, and depending on the geometry of the part, can be even more costly due to unused powders which often go unrecycled. Big hollow parts leave a lot of unused powder.

GE has just published a white paper showing a few different strategies for reusing AM metal powders, and we will summarize those strategies in this article.

Powder and Process Dependant

Not all metal powders are equal where it comes to reusability.

Materials such as Nickel alloys can be reused multiple times without much change to the shape of the powder particles or other physical properties. Nickel alloys are generally non-reactive.

Titanium alloy powders are reactive and accumulate oxygen as the number of reuse cycles increases, therefore having a negative effect on the part strength.

In addition, the process can affect the way that powders are contaminated. Electron Beam Melting (EBM) methods rely on vacuum, and trace amounts of oxygen can still remain in the system, and so can small amounts of moisture.

With laser melting methods such as Laser Powder Bed Fusion (LPBF), inert gases in the chamber help reduce oxygen buildup. But in both cases, wherever there is human interaction with the powder, contamination looms.

To that end, the best way of maintaining the quality of the part is to avoid any contamination at all. In other words, the best way to maintain quality while reusing powder, is to simply not reuse the powder at all.

But that’s not the answer you were looking for, is it?

The Answer

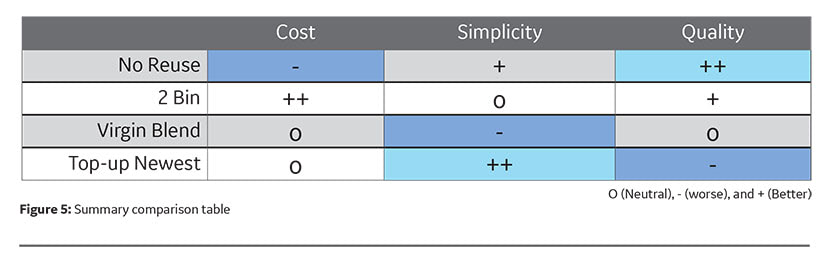

GE examines four different scenarios, and their effects on cost, quality, and simplicity.

You can see how these scenarios fare against each other in the table below.

In the table the four scenarios/strategies are:

- No Reuse: This is self explanatory. There is no reuse of powder. This route produces the highest quality parts but takes a hit on cost.

- 2 Bin: In the 2 bin strategy, the print is first completed with virgin powder and any remaining powder in the machine is unloaded and stored in a container labeled as “1 reuse”.

Subsequent prints use the remaining virgin powder from the same original batch and any remaining powder goes into the 1 reuse bin. When all the virgin powder batch is depleted, the 1 reuse powder is sieved and used to top up the machine. Any remainder of that already reused powder then goes into a second container labelled “2 reuse”. The process repeats until the specified number of reuses is reached, which will be dependent on the contamination of the powder. - Virgin Blend: The virgin blend approach uses virgin powder to top up used powder, therefore replenishing the missing elements in the used powder or diluting the levels of oxygen and other unwanted contaminants.

- Top-up Newest: This approach is a combination of the 2 bin method and the virgin blend method.

Used powder is rejuvenated but low reuse powders are used instead of virgin powder. You are effectively topping up the batch with the newest reused powders.

Effective Design of Experiments

In a nutshell, GE says that there is no one-size-fits-all solution for experimenting with reusing metal powders. Experiments are expensive and time consuming, especially when dealing with multiple factors and levels. Each experiment must be evaluated and the scope must be defined in advance to maximize effectivity.

“Conversations about powder reuse often begin with an aspiration to perform an all encompassing design-of-experiment that reveals everything about powder re-use,” says the white paper.

“Unfortunately, in our experience, this path is not practical in a business setting. We have found that the scope of the reuse study needs to be tightly defined and limited as much as possible, especially when all sources of potential variation are considered”.

What they are saying here is that because of the variation from case-to-case, a bespoke experiment using intrinsic knowledge must be employed to make high value discoveries rather than using a broad “screening experiment” approach.

If you wish to experiment with your own powder reuse strategies, then the list of 4 methods above should give you a solid place to start from.