While some in the manufacturing world are slow to adopt metal 3D printing, Roger Smith is not one of them. As the CEO of Sierra Turbines, he plans to completely revamp the microturbine industry by printing them.

Microturbines are incredibly complex components made of dozens of parts that are manufactured by a variety of means, so printing all of those parts is quite an undertaking.

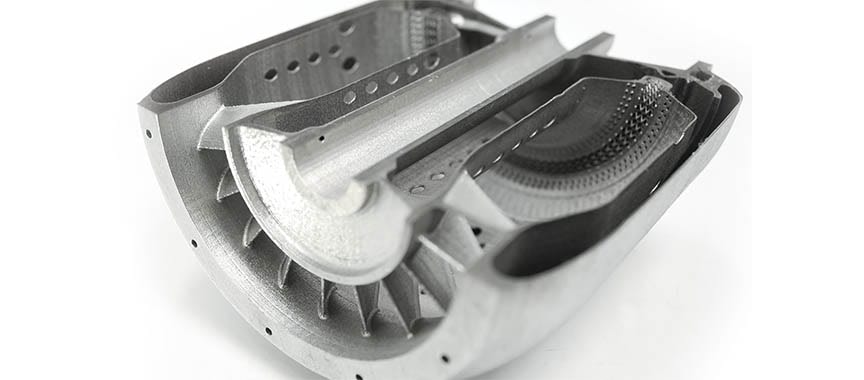

While they’re found in a number of applications, microturbines are most commonly found in the electric motors of unmanned aerial vehicles (UAVs). Auxiliary power units (APUs) in backup generators also rely on them. They are more than a little complex, with lattices, thin airfoils, and lots of interacting parts. The combination of those delicate features with the high temperatures they have to endure is what leads to the terribly short lifespan of microturbines; the time between overhaul for these small engines averages to about 50 hours. One of Smith’s goals is to dramatically increase that lifespan up to 1,000 hours.

If we as a country are to start building products in the U.S. again, we must develop better ways of designing and fabricating products. This includes less reliance on tooling, most of which has been shifted to China, but also an embrace of Industry 4.0 and other change-making technologies. Metal 3D printing is one of these change-makers. It’s far less wasteful than traditional manufacturing and presents endless opportunities for part consolidation, lightweighting, greater product efficiency… the list goes on. Roger Smith, CEO of Sierra Turbines

Smith’s team had already redesigned the engine core, consolidating it from 61 different parts down to just one. He contacted several firms that specialize in metal 3D printing in an effort to print the new design. Each one failed in a different way. Either they couldn’t print small enough features that are required for functionality, or supports were necessary but not possible to be removed from internal cavities, or the surfaces were too rough and not accessible to be machined smooth. That is, until they contacted VELO3D. “It was obvious to me early-on that the VELO3D platform offers a different approach to laser powder bed fusion (LPBF). For starters, their non-contact recoater blade is especially well-suited to print thin-walled sections. In some areas, our walls are less than one millimeter thick, and these tended to break off on other 3D printers,” said Smith.

The team at VELO3D worked with Sierra Turbines to optimize the design nTopology’s generative design software, varying the lattice size and thickness to maximize engine performance. Then they used the Sapphire printer to print it in Hastelloy X, a high-strength, low-creep metal that’s used heavily in aviation. Such a superalloy is necessary to reach Smith’s fuel efficiency demands because “the hotter you go in any gas turbine, the better the performance.”

VELO3D’s technology doesn’t require support material like most metal 3D printers, and that was critical to print this specific geometry that has lots of internal cavities. The prototype is really something to admire as it cut weight in half and increased power density from 200 watt hours per kg to 2,000, a tenfold increase. And it took only 50 hours to print, compared to untold months for the traditional component. It’s impossible to quantify all of the cost savings achieved through this, but they are significant. Smith is happy to bypass having to source all those parts from different vendors and assemble them with seals that will inevitably fail. He plans to print 95% of their microturbines, and eventually he intends to scale the technology up to the full sized gas turbines found in airliners. “VELO3D believes that you can use additive for full-scale production, and so do I. For future gas turbine development, we aim to leverage the power of additive manufacturing to integrate features such as an efficiency-boosting recuperator, printed-in sensors, and more novel insulating and cooling geometries.”