Researchers at YOKOHAMA National University (YNU) have developed a new method for fabricating complex oriented tissues using fluidic devices and 3D printing. The technique, published in ACS Biomaterials Science and Engineering, focuses on controlling the orientation of collagen fibers within tissues. This approach addresses limitations in existing methods such as magnetic alignment and electrospinning, which typically require magnetic beads or volatile organic solvents.

The process utilizes flow to orient collagen fibers and cells in channels constructed with a 3D printer. According to Kazutoshi Iijima, associate professor at YOKOHAMA National University, “By using a technique that uses flow to orient collagen fibers and cells, it is possible to fabricate complex oriented tissues with multiple directions in flow channels constructed using a 3D printer.” This method allows for the creation of tissue models that mimic structures found in the skin dermis or skull bones.

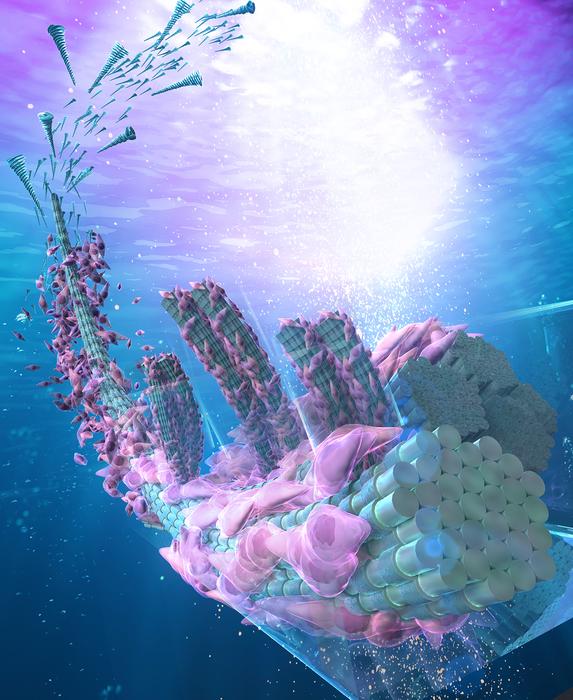

The research team used a type 1 collagen solution mixed with cells in 3D-printed fluidic channels. By controlling the flow through these channels, they achieved micro-oriented structures in both horizontal and vertical directions. This level of control enables more accurate tissue fabrication than was previously possible with existing technologies.

Professor Shoji Maruo, another author of the study, noted, “This system will lead to the customization of tissue-specific models using fine, multidirectionally oriented biomaterial scaffolds for the preparation of various oriented biological tissues.” The proper orientation of collagen bundles is crucial as it affects cell behavior and function, making this advance significant for tissue modeling.

The researchers plan to further develop the technology for potential applications in transplantation and in vitro tissue models. The study involved multiple contributors from YOKOHAMA National University’s Graduate School of Engineering Science, Faculty of Engineering, Institute of Advanced Sciences, and Institute for Multidisciplinary Sciences, with support from the university’s Instrumental Analysis Center.

Source: eurekalert.org