Lightweight and strong structures are a big deal for many industries such as construction and eco-friendly landscaping. While these are pretty useful materials, current methods have certain downsides. For example, automated fiber placement (AFP) and automated tape laying (ATL) can create parts with low mechanical properties and gaps in the structure. However, AFPALM technology presents a means of avoiding these issues using 3D printing.

AFPALM technology mixes 3D printing with automated fiber replacement, as the name suggest. German researchers at Technische Universität Braunschweig are running tests on it, showing how it works in a paper they titled A Novel Approach: Combination of Automated Fiber Placement (AFP) and Additive Layer Manufacturing (ALM).

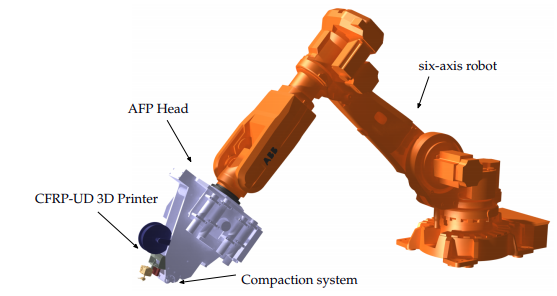

The method uses a six-axis robotic arm with a 3D printer and an AFP head at its front laying down reinforcing fabric. These pieces of fabric (prepregs) already contain resin and proper curing agents from the get-go. Prepregs are pretty easy to lay down on a flat surface but the new method displays a means of doing this over complex geometries.

Carbon Fiber Applications

The AFP head and the CFRP-UD 3D printer work in tandem to thermoplastic put in or thermoset unidirectional (UD)-Prepregs. In this case, they showcased a means for 3D printing to compensate for the flaws in the AFP methods. The combination of the two avoids the gaps one would normally expect in the automated fiber process. The 3D printed components filled in any incomplete areas without sacifricing quality in the overall components.

They created three samples: a laminate without gaps, a laminate with gaps, and a laminate in which 3D printing filled the gaps. The results showed an increase in tensile strength in the 3D printed parts while retaining low weight. They also made the parts much more consistent and homogenous without causing unnecessary material consumption.

Future versions of the technology could potentially feature a thermal camera that helps print over the gaps. This would allow for a faster process with all of the advantages listed earlier. The aerospace and construction industries would certainly make great use of such an invention.

Featured image courtesy of Technische Universität Braunschweig.