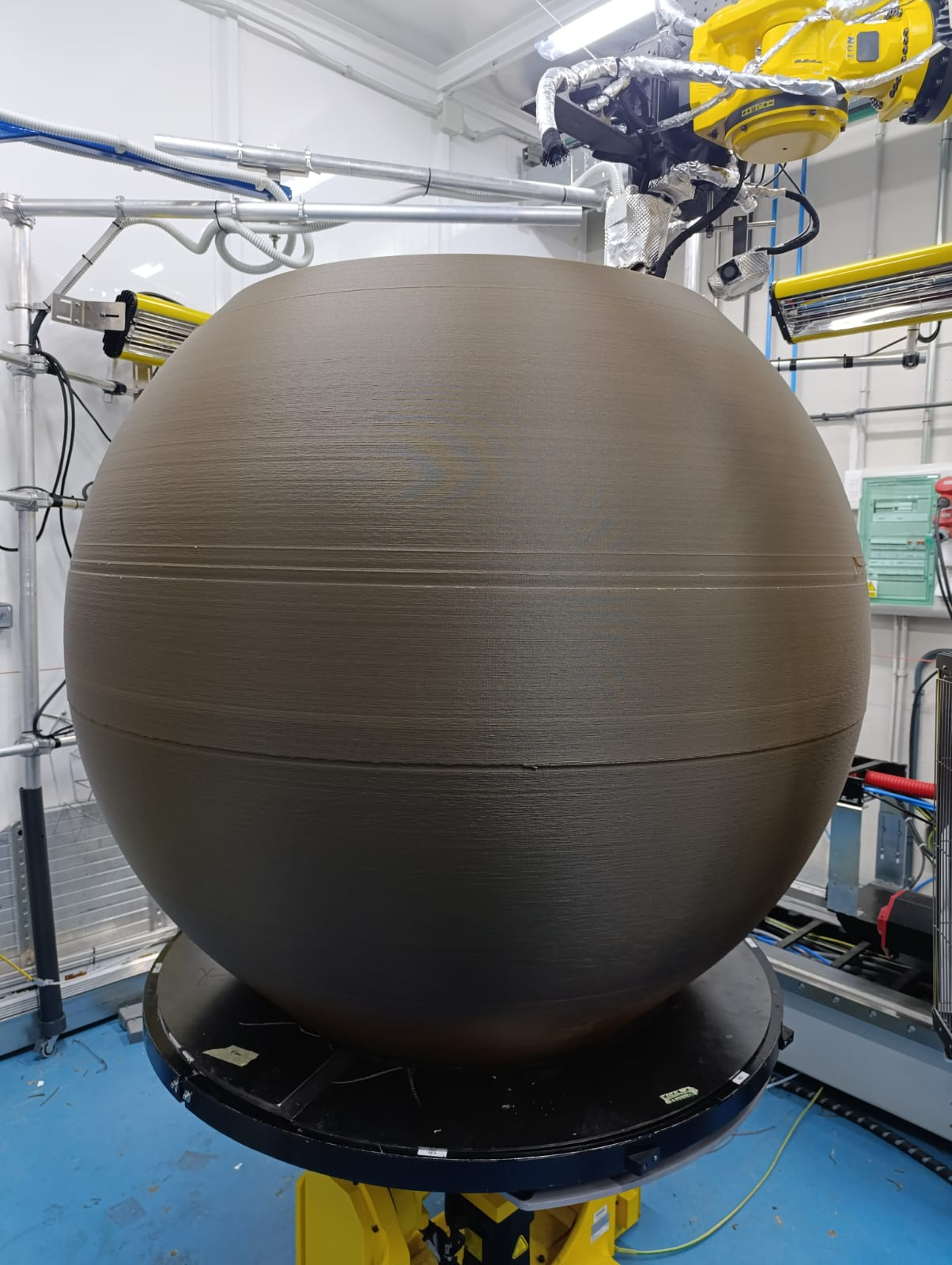

Aimen Technology Centre has completed the 3D printing of a cryogenic tank demonstrator for the OVERLEAF project. The Spanish organization manufactured a 1.5-meter-diameter inner tank designed to store liquid hydrogen (LH2) at extremely low temperatures for future aircraft applications. The project is led by Aciturri, a Spanish aeronautics company working on hydrogen storage solutions.

The tank design features a dual-component system combining an additively manufactured thermoplastic inner vessel with an outer carbon fiber structure. The inner component maintains the liquid hydrogen at cryogenic temperatures, while the carbon fiber exterior provides structural integrity. Aimen utilized large-format additive manufacturing with high precision to create the inner tank.

“This is a technological solution that will mark a before and after in the manufacturing of components for sustainable aviation,” said Pablo Romero, team leader of the Additive Manufacturing of Composites R&D group at Aimen. The manufacturing process required over 100 hours of continuous printing in a specialized robotic cell developed by Aimen. Real-time monitoring with thermal cameras ensured quality control throughout the extended build.

The manufacturing cell incorporated high-performance 3D printing systems alongside infrared heating technology to ensure proper adhesion between layers. This technical approach was necessary to meet the demanding requirements for hydrogen storage systems in aviation applications. The tank represents a significant step toward enabling hydrogen as an aviation fuel source.

Aimen collaborated with French research center Canoe to develop a new sustainable material for the project. The bio-based thermoplastic reinforced with natural fibers allows for printing strong, lightweight structures with reduced environmental impact. This material development aligns with the broader goals of creating more sustainable aviation technologies.

Source: compositesworld.com