MIT engineers have developed a new method to create artificial muscle tissue that can move in multiple coordinated directions. The technique uses a 3D-printed stamp with microscopic grooves to pattern muscle cells within a soft hydrogel material. This advancement represents a significant step forward in the field of biohybrid robotics, where machines are powered by artificially grown muscle fibers.

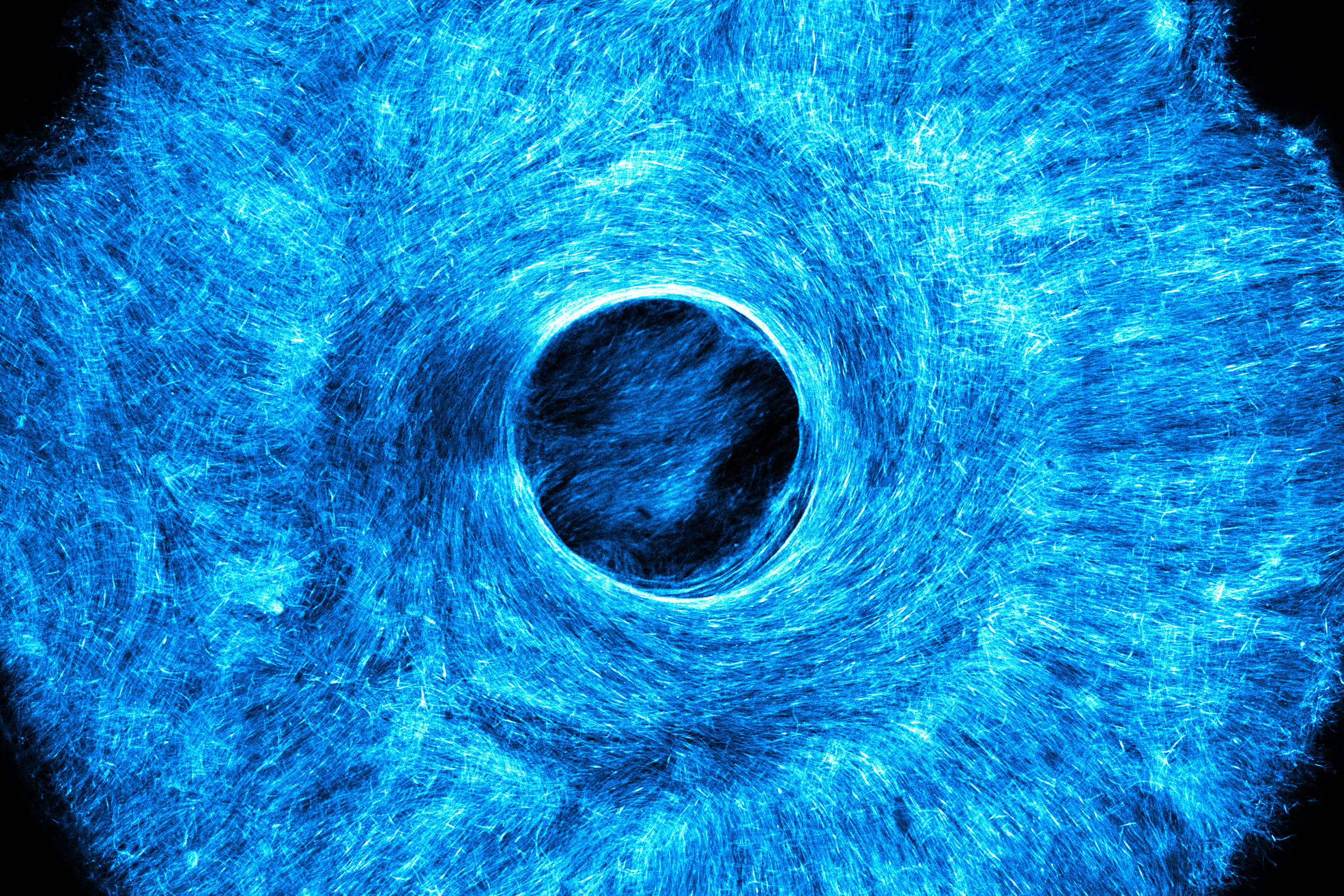

The research team, led by Professor Ritu Raman, demonstrated their method by creating an artificial iris-like structure that can contract both concentrically and radially. The stamp, which can be produced using tabletop 3D printers, contains grooves as small as a single cell width. When pressed into a hydrogel and seeded with muscle cells, the resulting tissue mimics the complex movement patterns of natural muscle.

“With the iris design, we believe we have demonstrated the first skeletal muscle-powered robot that generates force in more than one direction,” says Raman, who serves as the Eugene Bell Career Development Professor of Tissue Engineering at MIT’s Department of Mechanical Engineering. The cells used in the experiment were genetically engineered to respond to light stimulation, allowing the researchers to control the muscle’s movement.

The new stamping approach offers potential applications in both medical and robotic fields. The technique could be used to develop artificial tissue for treating neuromuscular injuries or create soft, biodegradable robots for underwater exploration. The researchers note that while they used skeletal muscle cells in their demonstration, the method could be adapted for other cell types.

The study, published in Biomaterials Science, was supported by various U.S. government agencies, including the Office of Naval Research, Army Research Office, National Science Foundation, and National Institutes of Health. The research team plans to explore additional muscle architectures and investigate ways to activate these artificial muscles for practical applications.

Source: news.mit.edu