When it comes to chemically resistant plastics commonly used in industrial 3D printers, stronger chemicals are often required for vapor smoothing. Many of these chemicals are dangerous, poisonous…or even carcinogenic.

What is needed is a proper system that can release the chemicals (whatever they may be) in the right proportions, in a safe, and controlled environment.

Enter the PostPro 3D from AM Technologies, which claims to do exactly that.

The system is an automated vapor smoothing system that can, according to the company, work on “over 100” different feedstocks for a range of 3D printer technologies.

In a new whitepaper from the company recently, they have highlighted the use of their machine of the Nylon 12 material, as printed by HP’s MultiJet Fusion printers.

In the paper, they have highlighted the two main areas one may be concerned about when embarking on larger-scale vapor smoothing processes.

These are surface smoothness (naturally) and mechanical properties.

Will the vapors smooth the parts and at what physical cost to the parts?

Let’s look at some tables and answer those questions.

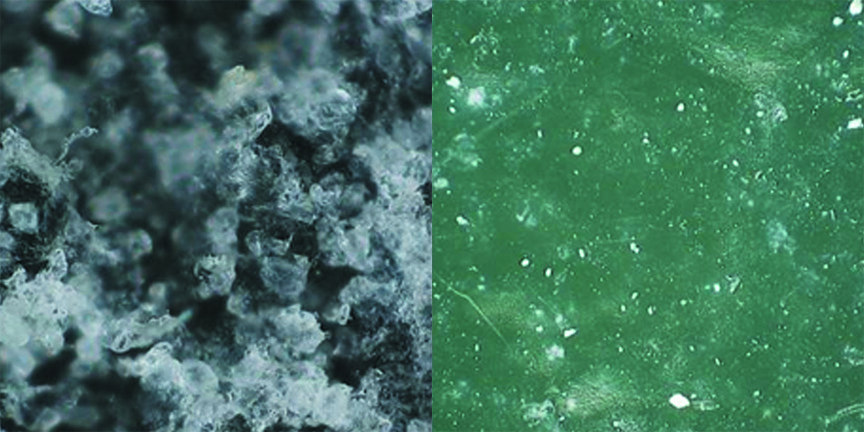

The three tables above show the surface roughness (Ra) in microns for the printed Nylon 12 parts, with three different finishing options from the smoothing system. The blue squares show the as-printed smoothness, and the black squares show the vapor-smoothed results.

In general, it seems this system can smooth prints down to less than 1 micron, which is comparable to injection molded parts. Nice to have that quantified to ASTM D7127 standards.

According to the paper, that’s a surface roughness reduction of over 1000%.

That’s great, but it’s basically melting the plastic with chemicals. That’s got to have some kind of downside, right?

Maybe. That’s kind of a relative question. Let’s look at the mechanical properties of the samples.

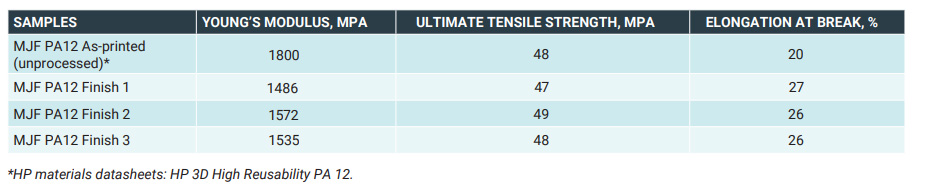

As you can see the parts are printed with the same finishes again, and also has an as-printed sample as the baseline.

Young’s modulus has been shown to decrease with the vapor treatments compared to the untreated parts. This means the chemical makes the Nylon samples more ductile.

Is this a good or a bad thing? Again, that’s totally relative. If you want a more ductile, slightly more stretchy but smooth Nylon part, then cool.

And we can see that the tensile strength varies a little with the application of the vapor too.

Overall, the process provides parts with improved shore hardness, improved tear resistance, elongation-at-break and naturally, a sub-micron Ra smoothness.

The PostPro systems come in two sizes, the PostPro3D (90 litres) and the PostPro3D Mini (50 litres).

Most importantly they are automated to perform the smoothing task in under 2 hours, in a repeatable manner.

You can find out more about the vapor solutions over at this link, and you can even send them one of your own printed parts and ask them to do their treatment on it to help you assess the system.