Metal Binder Jetting and Metal Injection Molding processes have faced challenges related to part distortion and sag during sintering. Traditional methods relied on support structures or ceramic setters to counteract this issue. However, researchers at HP Labs have developed a novel solution – a shape-retaining-stimulus coating that eliminates the need for support structures during sintering.

Solving the Sag Problem

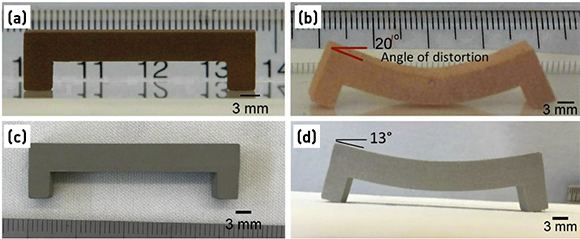

The researchers applied shape-retaining-stimulus coatings to copper and stainless steel green parts and conducted thermal treatments. The coatings demonstrated the ability to resist sag during sintering. Copper parts with a 28 mm overhang and stainless steel parts with a 33 mm overhang remained intact without sag after sintering. The coatings formed a metallurgical bond with the part surfaces, providing strength and stability during the sintering process.

Through various thermal treatment temperatures, the researchers discovered that the coatings form a strong bond with the part surfaces and prevent sagging. The coatings undergo a chemical reaction during sintering, transforming into a porous network that adheres to the part surfaces. Multi-stage sintering increases the volume of particle-neck-bond, enhancing the strength to support itself. Parts with overhangs at different angles, including 30°, 45°, and 60°, were successfully sintered without sag.

Applications in Stainless Steel

The researchers also explored support-free sintering of 316L stainless steel parts using a specific shape-retaining-stimulus coating. The stainless steel parts showed no sag, and after cleaning, no traces of the coating remained. The coating ingredients bonded to the part surfaces during the initial stages of debinding and sintering, preventing sag under gravity.

The development of these coatings also revealed the possibility of inducing controlled deformation in the part during sintering. This phenomenon allows for the transformation of a 3D printed green part into a new shape using an external stimulus coating. By eliminating the need for support structures, these coatings open up new design possibilities and opportunities for innovation in the Binder Jetting and MIM industries.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.