A team of researchers from Michigan Technological University have demonstrated printing of carbon nanotube (CNT) infused epoxy inks, and have published a paper recently in the Additive Manufacturing journal sharing the results.

The research compared printed structures made from epoxy, nanoclay, and various concentrations of the CNTs ( 0.25, 0.5, and 1 % by volume). Nanoclays are nanoparticles of layered mineral silicates, and they are added to provide stiffness, toughness, strength, to polymer matrices, such as epoxy.

CNTs are prized for their high specific strength. CNTs are not so easy to manufacture at scale however, but this research may show one means of scaling up.

By use of a direct-write 3D printing process, samples were printed to assess the various mechanical and electrical responses as the CNT content was varied. You can see some of the printed samples in the photo below.

The CNT-infused specimens showed an increase of 31% for tensile strength, 59% for flexural modulus and 61% for flexural strength when compared to structures made from only epoxy and nanoclay. These highest values were found to come from an optimum CNT concentration of 0.5% CNT by volume.

In addition, specimens at this concentration showed electrical conductivity values of 2.4 × 10⁻⁸ S/cm.

What does this mean? It means that these CNT-epoxy polymer inks are strong and conductive, and therefore may have applications in aerospace and electronics manufacturing. In particular, the researchers hope that these functional inks may even replace epoxies themselves.

The CNT concentration of 0.5 vol% was found to be the optimum condition for enhancement of mechanical properties; an average increase of 61, 59, and 31% was measured for flexural strength, flexural modulus, and tensile strength, respectively, compared to the 3D printed epoxy-nanoclay nanocomposite structures.

The electrical conductivity of 2.4 × 10⁻⁸ and 2.2 × 10⁻⁶ S/cm was measured for the nanocomposites containing 0.5.

“In comparison with steel and aluminum, we see 80% weight reduction with epoxy composite with [the[ same strength,” said Masoud Kasraie, a graduate engineer on the project.

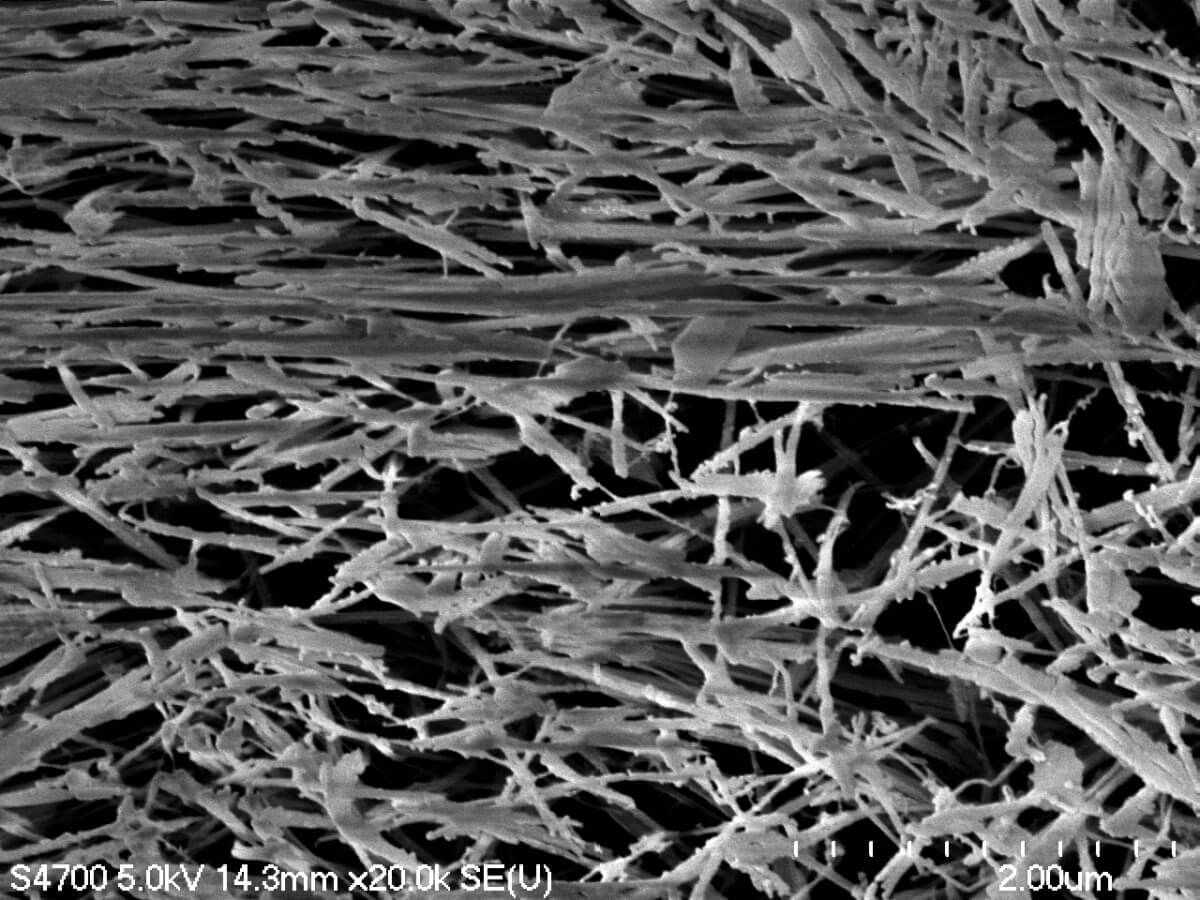

The addition of CNTs has shown to reduce crack propagation in the epoxy matrix.

“When something breaks, a tiny crack starts from a microscale defect and progresses until it breaks the entire structure,” said engineer Parisa Pour Shahid Saeed Abadi.

“Nanocomposite features make bridges in those cracks and don’t let the cracks grow. This is one of the mechanisms through which carbon nanotubes increase the mechanical strength of the material.”

If you would like to read more about the research, whichs contains information about the morphology and rheology of the materials, then you can find the paper over at this link.