3D printing has been making its way through numerous industries but there are still factors inhibiting wider adoption. Aside from the usual concerns like certifications or strength, another issue the industry is looking to address is that of truly multi-material printing. So far, in comparison with say injection molding, 3D printers are resigned to a narrower range of materials in one object. Especially when it comes down to resin 3D printers or Vat Photopolymerisation technology. Although, scientists at the University of Wisconsin–Madison are looking to change this. The university developed a 3D printer that is able to print multi-material objects by controlling light wavelengths and emitting them selectively.

Multi-Material Resin 3D Printing

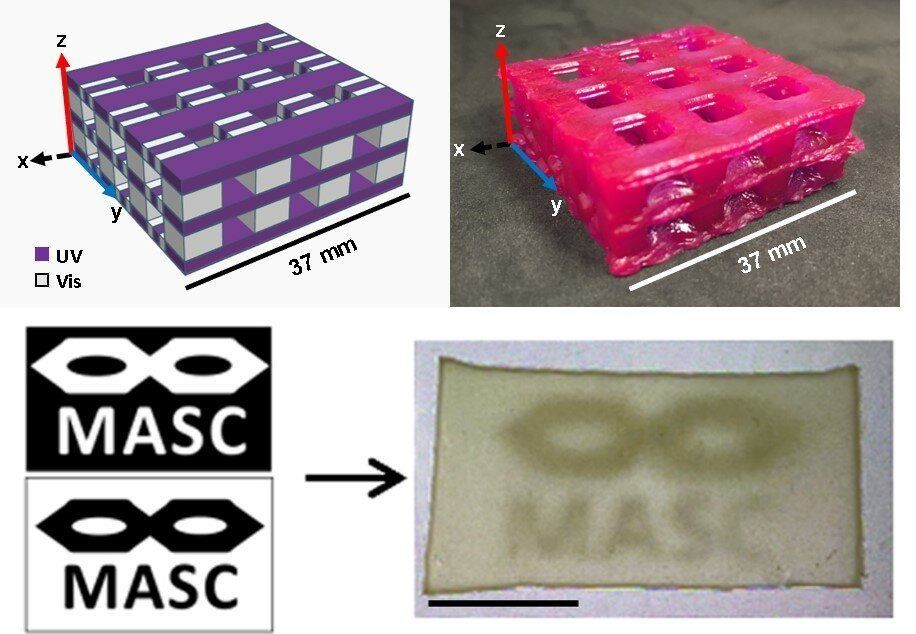

In contrary to ordinary light-based printing techniques this method uses different wavelengths of light to control how starting materials polymerize into different sections of the solid product. It also generates various light patterns, which gives the method spatial control needed for multi-material parts.

“This is a shift in how we think about 3D printing with multiple types of materials in one object,” UW–Madison Professor of Chemistry A.J. Boydston says. “This is more of a bottom-up chemist’s approach, from molecules to networks.”

Multi-material methods often utilize separate reservoirs of materials to produce a mix in correct positions. What the researchers settled on is far more practical in comparison. For one thing, it uses a single vat to generate the object, eliminating the need for multiple material sources. This allows for a more overall compact, streamlined process with less mechanical complexity.

Researchers have to create digital images, each controlling light wavelengths of a different value. When these images come up on top of each other, they produce a 3D design that a projector can display over the vat. The design is made up of patches of different wavelengths of light, some visible and others not. Layers build up one-by-one, different areas and light wavelengths corresponding to different properties and materials.

The method can effectively imbue different characteristics, such as different regions of varying stiffness, into a single print by controlling light wavelengths. One of the obstacles to this was getting two different monomers to behave similarly in a single vat. The researchers had to find suitable chemicals and especially ones with similar curing rates.

The technology could be of great use in art and design, but it is far from perfect. “At this stage, we’ve only accomplished putting hard materials next to soft materials in one step,” Boydston says. “There are many imperfections, but these are exciting new challenges.”

Featured image courtesy of UW Madison.