Chinese regulators have approved the first laser 3D-printed total knee implant, developed by Naton Biotechnology. The approval follows new research that addressed key challenges in manufacturing metal implants using laser powder bed fusion technology.

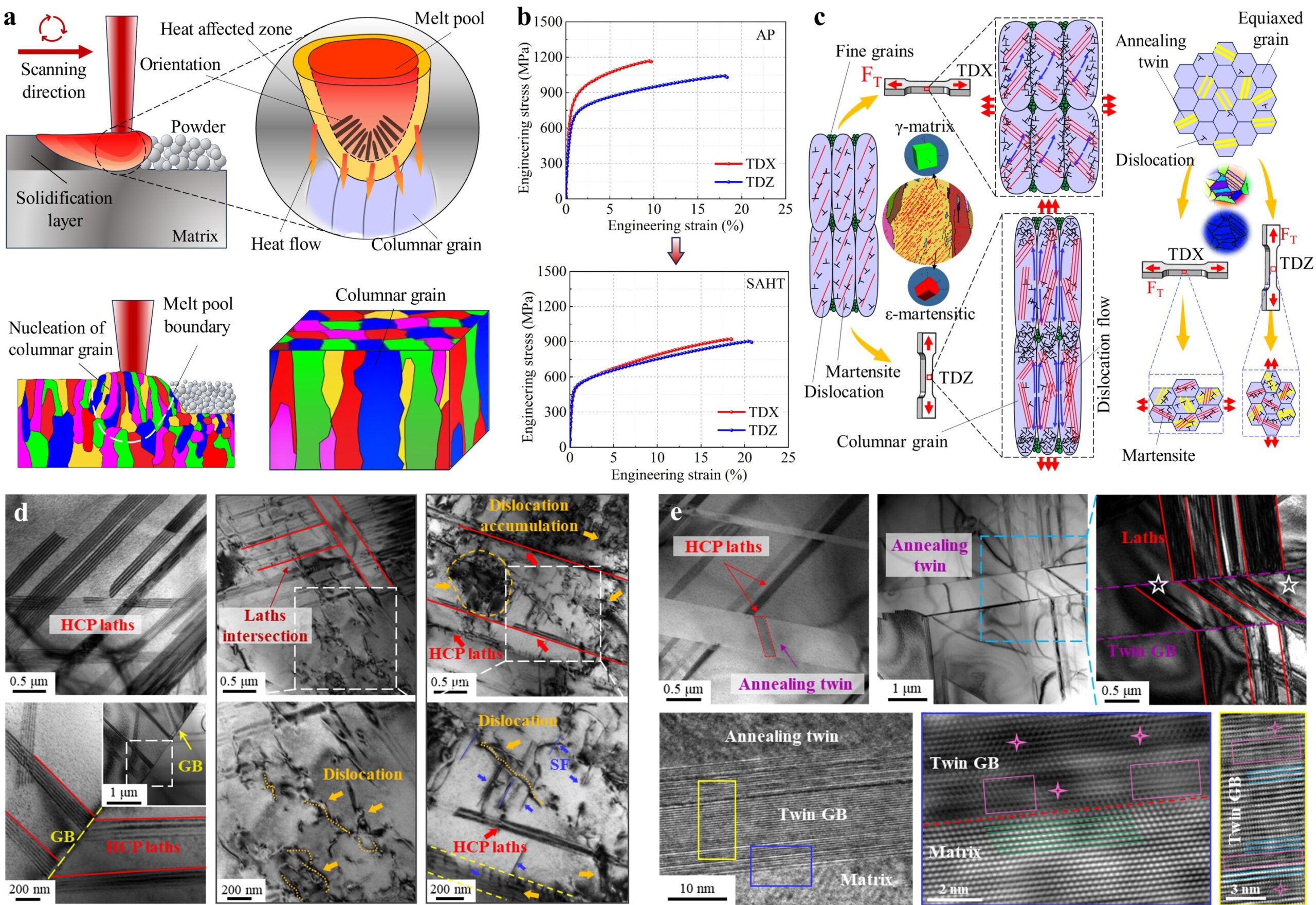

A team led by researchers from South China University of Technology and Beijing Tsinghua Changgung Hospital identified significant inconsistencies in 3D-printed cobalt-chromium-molybdenum (CoCrMo) alloy implants. Testing revealed that the material’s elongation varied from 19.1% in one direction to 9.3% in another, highlighting potential reliability issues for medical applications.

The researchers developed a two-step heat treatment process to improve the material’s uniformity. The process involves heating the material to 1150°C for an hour followed by water cooling, then reheating to 450°C for 30 minutes. This method resulted in more consistent material properties, with ultimate tensile strength reaching 906.1 MPa and 879.2 MPa in different directions.

The study, published in Materials Futures, demonstrates how optimized heat treatment can enhance the strength and reliability of 3D-printed metal implants. The findings address important safety concerns for medical implants, which must maintain consistent performance under various directional forces within the human body.

The research team is now exploring additional surface treatments to improve wear resistance and biocompatibility. These include shot peening and ultrasonic peening techniques, which could extend the longevity of implants under daily use conditions.

Source: medicalxpress.com