In-situ monitoring of the status of feedstocks is a popular topic among researchers, regardless of the type of printer being used.

Inroads are being made towards greater quality control and repeatability by use of various sensors in the printing process in both metal and plastic printing, and these technologies may very well end up in consumer products…especially if there isn’t too much expensive hardware involved.

One team at Penn State University is carving one such inroad in the area of FFF printing, and they have published details about their research into computer vision aided filament measurement in the Manufacturing Processes and Systems section of the Materials journal.

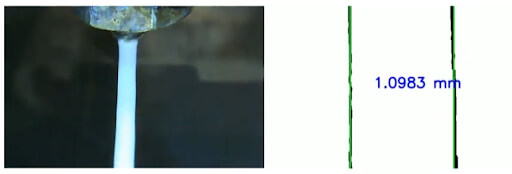

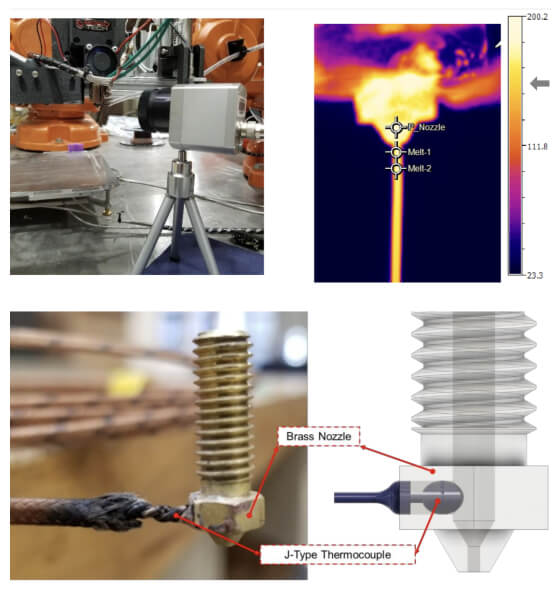

Using a microscope camera, an FFF printer and a whole bunch of code, researcher Rakshith Badarinath set about using computer vision to detect the width (and hence, volumetric flow rate) of the extruded filament as it was exiting the heated nozzle. In addition, a thermocouple was added to the nozzle itself to monitor the temperature to determine any impact this also had on the extruded filament. The nozzle exit temperature is critical in determining the interlayer bond strength (and bond quality) of the deposited filament tracks.

As the filament is deposited, the microscope camera detects the edges of the filament before applying an algorithm (named the “Robust Extrusion width Recognizer (REXR) algorithm) to measure the width. From the width, the volume can be determined, and when plotted against time, a volumetric flow rate is obtained.

The extrusion width measurement was found to be within 0.08 mm of caliper measurements and the determined flow rate was found to closely track that which was specified in the slicer software, meaning that the experiments successfully demonstrated this method of in-situ filament monitoring.

Video: Real-time Vision based Extrusion Width Measurement

Quality Control

Defective prints can cost time and waste materials, so development of process monitoring technologies is of vital importance to industries wanting to improve quality and repeatability while reducing costs and reworks.

Real time sensing of key process parameters not only improves the quality of the extruded materials, but can help to better understand the physics of the FFF process, which can in turn, help to build better models for prediction. One day we may even see Digital Twins of printing processes, all with sensors and algorithms at their core.

You can see the modified brass nozzle used in the experiment in the image above, along with some IR images of the filament extruding from the hot nozzle. 2 types of common filament (PLA and PETG) were used, and they used a robotic arm-type printer.

The researchers intend to continue to develop the process and state that improvements in the real time measurement rates of the deposition process need to be improved before the tech is ready for industry.

Given the demonstration of the technology working, it doesn’t seem like too much of a stretch to say we will see some form of this vision based approach to filament sensing in a printer near you in the not too distant future.

You can read the full paper, titled “Real-Time Sensing of Output Polymer Flow Temperature and Volumetric Flowrate in Fused Filament Fabrication Process’ (free access), at this link right here.