In the domain of electric motion, motors often take the spotlight, leaving linear movement seekers in a quandary. Traditional options like electromagnetic solenoids pose drawbacks (largely cost related), pushing enthusiasts to explore alternatives. Enter DIY linear actuators, a solution by a maker by the name of “PHYTION”, who has demonstrated the creation of a homemade linear actuator using economical components and 3D printed elements.

Linear actuators, with variations like hydraulic, pneumatic, and electric types, cater to diverse needs. PHYTION’s tutorial focuses on an electric variant utilizing a lead screw mechanism reminiscent of a 3D printer’s Z-axis. This ingenious design, although sacrificing speed for torque, ensures efficient conversion of rotary motion to linear force.

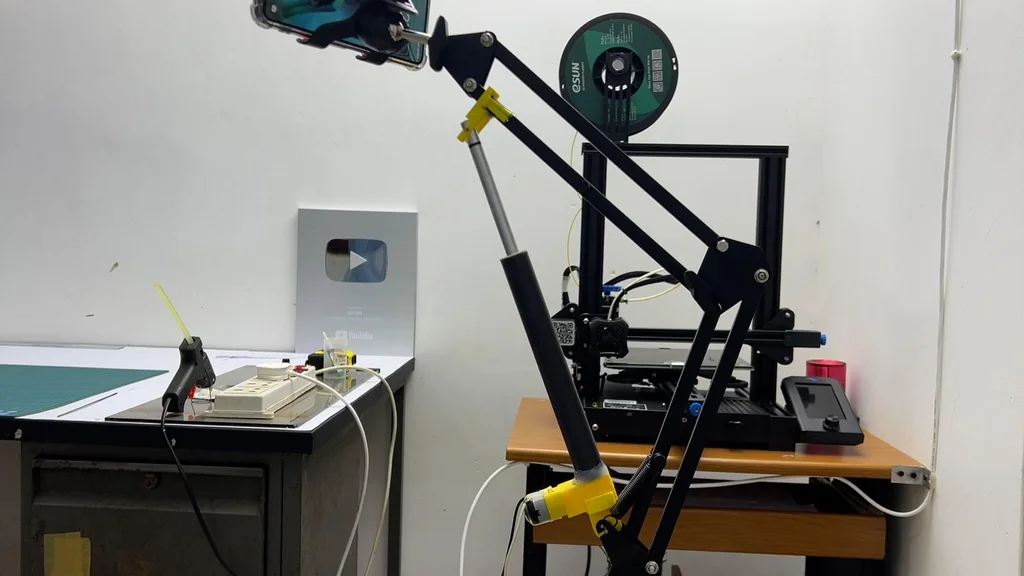

The tutorial emphasizes cost-effectiveness, utilizing standard nuts, basic threaded rods, aluminum tubes, and PVC pipes, all readily available from a hardware store. An affordable electric gear motor provides the necessary rotary input, while 3D printed components serve as structural support and mounts.

Fabricating this linear actuator primarily involves 3D printing the components, cutting tubes to size, and assembling with adhesive. While not intended for heavy-duty tasks, this DIY creation proves adept for robotics enthusiasts, offering commendable torque and precision, albeit requiring additional hardware for position detection.

The DIY linear actuator project illuminates the potential of merging affordability with functionality. As enthusiasts delve into personalized motion systems, the future holds promise for more tailored solutions at a reduced cost, thanks to the accessibility of 3D printing and other off-the-shelf technologies.

Source: hackster.io

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.