Last week we took a look at some promising research that utilized processed pineapple leaf fibers for the production of biocomposites.

Bioplastics and biocomposite systems are great, and the research of such things should be lauded, especially if they make use of waste matter such as leaves, fruit skins or husks.

So this week, let’s see how durian-based biocomposites compare.

King of Fruits

The durian is known as the King of Fruits. It is renowned for its shape, taste, texture and smell, which many find to be an acquired taste, putting it mildly.

It’s very popular in Malaysia, and it is in this South East Asian peninsula where researchers from different institutes have been looking at different approaches for making durian into biocomposites. The durian husk consists 60.45% of cellulose, 13.09% of hemicellulose, and 15.45% of lignin, which are all useful bio-polymers, and so are useful as filler in biocomposites when mixed with PLA or natural oils.

According to the one group of researchers, 3,800 metric tons of durian fruit were produced in Malaysia in 2016 generating an estimated 2,280 metric tons of husk. That’s a lot of filler.

PLA + DSF

The first research we will look at comes from Taylor’s University, HELP College of Arts and Technology, and The University of Nottingham (all in Malaysia), who have blended durian skin fibers (DSF) with neat PLA to directly form 3D printer filaments.

To prepare the filament, the durian husks were washed with tap water and cut into small pieces, dried, ground into short fibers and passed through a sieve with a mesh size of 600 micron to get a consistent size of fiber. The fibers were then dried again before being blended with the PLA and molded into sheets. The sheets were cut into standard ASTM D638 dogbone specimens for tensile testing.

The unfilled PLA proved to be superior, with the durian composite PLA having a tensile strength of just 11 MPa. The stiffness was found to increase significantly, but it was found to be too brittle to be of any use.

So while the results were not astounding, the team noted that with increased fiber size, the durian/PLA filament could see an increase in strength.You can read the full research paper at this link.

Just Add Oil

The research from the International Islamic University Malaysia (IIUM) team made use of epoxidized palm oil (EPO) as a plasticizer mixed with the durian skin fibers and PLA. The result is a biodegradable biocomposite that can be molded into sheets for use in food packaging and filament.

The addition of EPO was shown to increase the ductility of specimens, and according to the researchers, this can be explained by the theory of gelation where the presence of the plasticizer weakens the polymer structure, making the samples less brittle.

Of course, anyone who has spent the “haze season” in South East Asia will know that palm oil is not the most ecologically friendly material to use, due to the slash and burn practices involved in palm oil production that results in a thick blanket of smoke descending on the region every year.

That said, it is the highest yielding of oil producing plants, so as long as the environmental impact is managed, then use of palm oil is an interesting proposal.

In terms of biodegradability, in a different experiment the researchers buried some of the material and found that after three months buried in soil, about 83 percent of the packaging had degraded. As long as the palm oil is sustainably grown and harvested, this method of manufacturing biocomposites using natural oils could prove to have utility, especially as a molded plastic.

You can read more about the tensile testing of EPO / DSF / PLA biocomposites at this link.

Freeze Dried

The third method involved freeze dried extraction of durian fibers blended with PLA and cinnamon oil rather than EPO.

By using freeze drying, researchers from IIUM were able to reduce the size of particles, creating a durian skin nanofiber (DSNF). The DNSF was added to a PLA base which had been plasticized with cinnamon essential oil (CEO). The cinnamon oil also has antimicrobial properties.

Freeze drying was also selected as the process extends the shelf life of the biomatter in question.

This DSF was initially cut, dried and ground before being sieved to a consistent 90 micron particle size. The sieved DSF was then added to 100ml distilled water with 600 μL acetic acid and then frozen at –20°C. The aqueous suspension then underwent a lyophilization process to produce the DSNF with particles measuring in the nanoscale range. After further processing, the materials were cast into flat sheets and then trimmed to the correct sample size for testing.

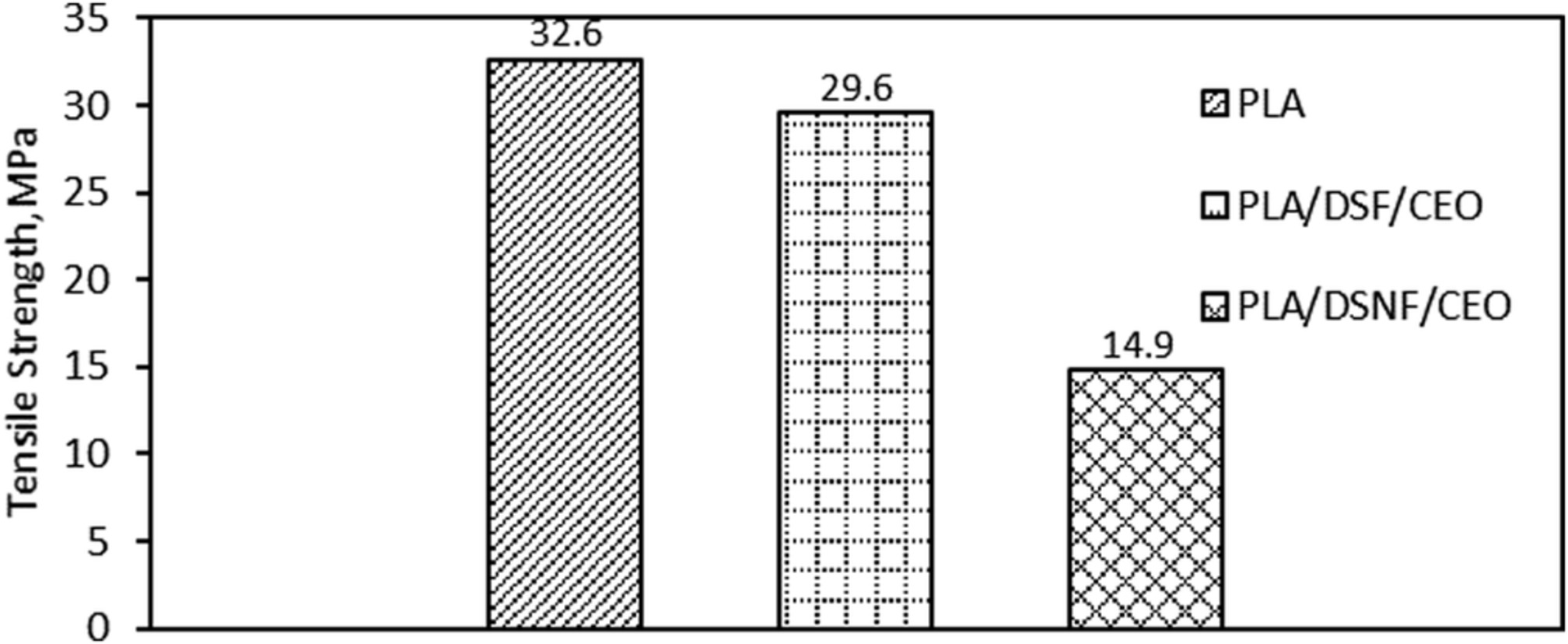

Three differently composed sample types were produced. One was made from PLA, the other was PLA / CEO / DSF, and the final batch was composed of PLA / CEO / DNSF.

The researchers had expected DNSF samples to possess superior tensile strength compared to the DSF loaded samples, but it was found that the DNSF samples were much weaker. This was thought to be the result of an agglomeration of the smaller DNSF particles, and also the hydrophobicity of the resulting biocomposite system, which causes poor interfacial adhesion between the components.

However, this particular research showed that the PLA / DSF / CEO combination was almost as strong as the unmodified PLA.

Scanning electron microscopy (SEM) showed the length of the DSF fibers to be in the range of DSF 32.38 and 67.64 μm, and the freeze dried DNSF to be in the range of 0.73 to 2.72 μm, although it is note that these small DNSF particles are agglomerated (recombined).

You can read about this research over at this link.

Final Thoughts

While the first researchers stated that higher tensile strengths could be attained with longer fiber lengths, their already long fibers measuring 600 microns were shown to perform badly when mixed with neat PLA yielding only 11 MPa in tensile tests.

Conversely, the final research we looked at showed that it was possible to obtain tensile strength values of 29.6 MPa with fibers almost 6x shorter!

What is going on here?

The addition of oils such as palm oil and cinnamon oil as plasticizers clearly has had an effect on the strength and ductility of the samples. In addition, it seems that at first glance, the methods of preparing the DSF could potentially affect the characteristics of the produced fibers.

A more consistent means of producing DSF is needed to fully assess the effects of these factors.

But given the results of the cinnamon / DSF / PLA experiments in the final research group, which yielded mechanical properties comparable to neat PLA, it seems that continued research into durian biocomposites may provide…fruitful.

Are you a university researcher working on plant-based fiber biocomposites?

Tell us about your research with our contact form and we will be happy to share your work!