FlashForge is getting ready to release a whole new line of specialty 3D printer filament with a lot to offer. The new line will add 16 filaments in total, covering all sorts of functionalities and characteristics to meet all sorts of 3D printing needs, from toughness to flexibility to impact-resistance to aesthetics. The range will be available all over the world very soon.

Looking over the list one can see that they share 2 over-arching similarities. For instance, they are all available 1.75 mm, with some also being available in 3 mm versions. Most have tenacity as a core feature, according to FlashForge’s description of their attributes. Other than that, they range just about every temperature, color and function one can think of.

Breakdown of the Filaments

PLA, ABS, ABS Pro, HSPLA & PLABS

Let’s start with the classics, PLA and ABS, and FlashForge’s specialty spins on them. The company is launching both ABS and ABS pro filaments. There are some interesting differences between these two, with the pro between tougher and featuring more thermo-stability. The ABS Pro also requires a lower minimum bed temperature (50 °C compared to ABS’ 80 °C). Similarly, PLA comes comes in 2 forms: regular and HSPLA. FlashForge designed the HSPLA for not just high-speed printing, but also faster melting, solidifying and flowing.

Then there’s the PLABS filament which combines the strengths of both ABS and PLA but without the smoke or fumes you get from ABS. As such, this makes it a great filament for complex, high-precision prints. With a print temperature of 200 – 240 °C it requires a temperature range a bit higher than PLA but definitely lower than ABS. Its the best of both worlds. Although, currently, it only comes in a single color.

Flexibility & Toughness

In terms of characteristics, some will probably want something less stiff. For them, FlashForge have got the “Elastic” and “Flexible” filaments. The flexible filament presents bright colors, easy feeding to the extruder and great resilience. The Elastic filament is even more flexible, offering corrosion and scratch resistance on top of that.

Another criteria that pops up often are the tougher and more impact-resistant thermoplastics. Nylon fills this category, being better for industrial prototyping and everyday items. Similarly, HIPS filaments provide impact resistance, while also being a great support material due to their ability to dissolve in Limonene.

The Food-Grade Plastics

Printing Tupperware and other household items can be a chore. Which plastics should you use and do they meet food-grade standards? That’s where PC, PETG and Polypropylene come in. FDA approved, tough and heat durable, all 3 provide some industrial capabilities. Both PC and PETG also bring in quite a high rate of light transmittance to the fold (85% for the former, 90% for the latter).

They each have their individual advantages of course. PETG is best for printing transparent materials, printing out with very few marks and notable abrasions. PC, on the other hand, is flame retardant and PP has enough viscosity to actually clean the extruder.

Please know that these filaments are food-grade in its raw form. To keep these materials food safe, the whole process of production needs to follow these standards. When you process these materials through a 3D printer that is also used for printing with non-food safe materials (like ABS, PLA or Nylon), the final product can no longer be labeled as food safe.

Pearl, Wood and Thermochromic

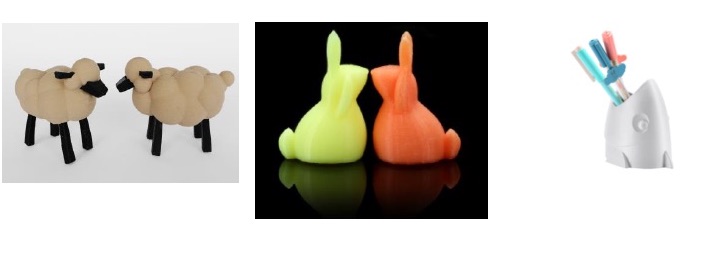

What unites these 3 filaments is that they bring a certain aesthetic flash to their designs. The wood filament is just that: it looks like fine, polished wood. It is a mix of poplar, environmental PLA and actual wood textures. Similarly, Pearl is another filament with a pearl-like sheen, most suitable for high accuracy objects. Pearl is a mixture of bio-degradeable PLA, PHS and PBS.

The thermochromic material actually changes colors in reaction to temperature. When it crosses the 33 °C threshold, it turns from Orange (at the lower temperature) to Yellow. It can add a nice dimension to any print or artwork users may want.

All images courtesy of FlashForge.