Dr. Sanna Siddiqui, an esteemed assistant professor of mechanical engineering at Florida Polytechnic University, has recently been honored with the prestigious CAREER award from the National Science Foundation (NSF). This achievement has granted her a substantial research fund of $536,110 over a span of five years. The primary objective of this grant is to delve into the intricate dynamics of fatigue and performance failure inherent in metal components manufactured through cost-effective 3D printing methodologies.

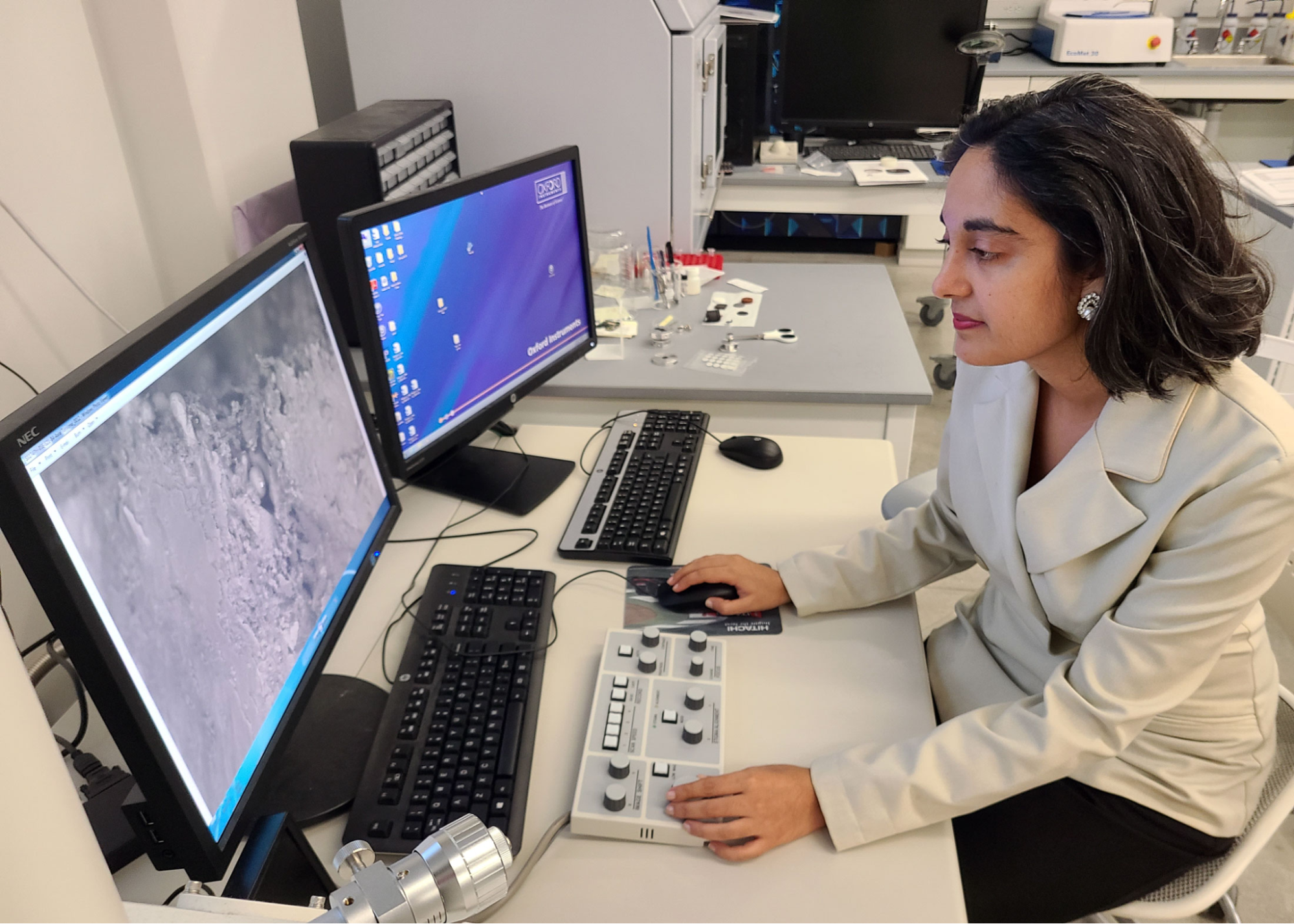

The crux of Dr. Siddiqui’s study revolves around the evaluation of a nickel-based superalloy, a material commonly employed in critical aerospace and energy propulsion systems. Through meticulous experimentation and analysis, she aims to ascertain whether these components, when fabricated via 3D printing, can exhibit comparable performance characteristics to those produced with more conventional, albeit pricier, materials.

Central to the 3D printing process under investigation is the utilization of a composite mixture comprising plastic filament and metal powder. By subjecting this amalgam to elevated temperatures, the plastic component undergoes dissolution, leaving behind a resilient metal structure that forms the basis of the final product.

“Many industries including aerospace and automobile manufacturing are shifting towards 3D printing because you can rapidly prepare parts, with flexibility in geometric designs, and hence improved efficiency,” said Siddiqui.

“The question is, can these 3D printed materials perform as effectively as their counterpart materials developed through prior conventional manufacturing methods or not.”

The receipt of the NSF CAREER award represents a significant milestone in Dr. Siddiqui’s academic and research trajectory, underscoring the recognition of her scholarly contributions and the potential impact of her endeavors within the realm of additive manufacturing.

Source: thetampabay100.com

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.