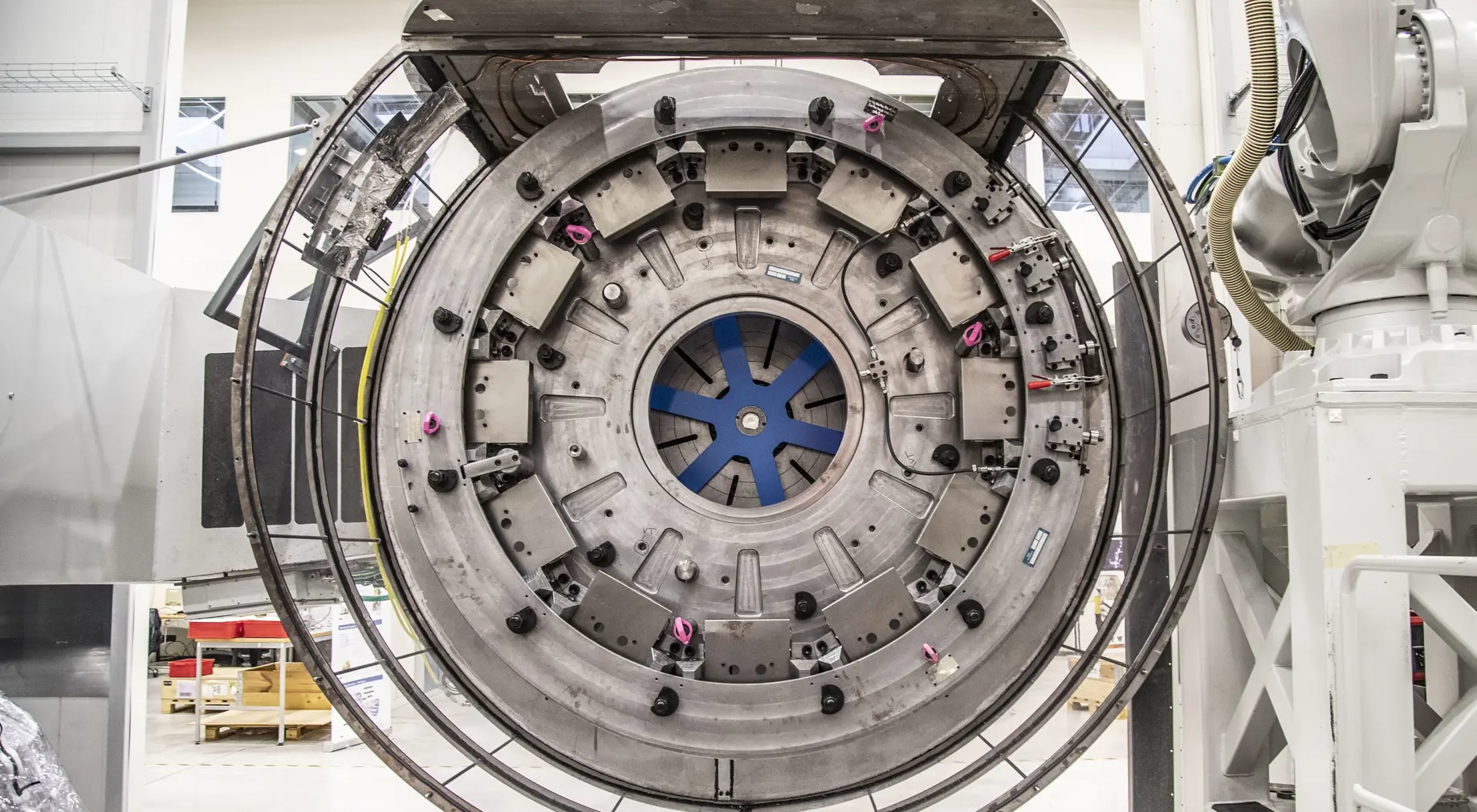

GKN Aerospace announced the expansion of its Newington, Connecticut facility to include a new production line for additively manufactured Fan Case Mount Ring (FCMR) components. The FCMR is a critical part of the Pratt & Whitney GTF engine used in Airbus A220 and Embraer E195-E2 aircraft. The expansion will create new jobs and support the company’s goal of achieving 100% serial production by the end of 2025.

The FCMR program represents the largest flight-critical additive component to receive FAA certification. Currently, the component’s core structure is produced at GKN Aerospace’s facility in Trollhättan, Sweden, with final machining completed in Newington. The Connecticut expansion will enable full-scale production at a single location.

According to the company, its proprietary additive fabrication process is projected to achieve over 70% material savings while reducing production lead times. GKN Aerospace currently produces approximately 30 FCMR units per month at its Swedish facility. The expansion aims to support increased production volume and meet growing market demand.

“This expansion in Connecticut marks a major milestone for GKN Aerospace and our Fan Case Mount Ring programme,” said Joakim Andersson, President Engines at GKN Aerospace. “We are proving that additive fabrication is not only technically transformative but also delivers real-world benefits in sustainability, lead-time and predictability for our customers.”

GKN Aerospace operates two facilities in Connecticut, employing more than 450 people across the state. The Newington expansion builds on the company’s $50 million investment in 2024 to expand additive fabrication capabilities for civil and military engine platforms globally.

Source: gknaerospace.com