With the field of spaceflight and aerospace manufacturing buzzing with new entrants, it’s sometimes hard to stand out. These are start-ups like no others, building possibly the hardest machinery to make and testing them. So, maybe companies can take a page from Relativity Space, which 3D prints rockets cheaper than competitors. The Mark Cuban-backed company has been very reliant not just on 3D printing, but counter-intuitively, on lean hiring practices.

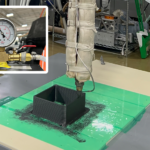

It was 2015 when Tim Ellis and Jordan Noone were focusing on AM processes at Blue Origin and SpaceX. While there, both of them recognized that the fully 3D-printed rocket was the inescapable future. The cost savings alone, were worth it, not to mention the ease of building. We’ve covered their prolific use of the Stargate printer, one of the largest additive manufacturing machines in the world. The printer is now busy making the Terran 1 rocket, which will be cheaper than competitors on a per kilogram basis.

In conjunction with their reliance on 3D printing, the company has become notorious for their size. 25 employees may seem just like a lot for any startup, but that’s a sparse group to have in an aerospace company. This is especially interesting considering how they’re printing larger rockets than the competition.

Lean & Mean

The aerospace manufacturing field has a ton of start-ups now. Many are getting ready to launch or have already launched satellites. While the field is occupied, they are all learning from each others processes, so the field as whole is getting smarter. Relativity Space still manages to stand out because of their lean and mean hiring practices.

For one, they’re avoiding the trap of over-hiring and thus keeping an efficient team. Next, they can rely on 3D printing with a small team because they built their own. As a consequence of having built their own printer, they have the advantage of starting with a clean slate and suiting it to their specific needs. This level of machine specialisation plays into their hands perfectly.

The company is making great strides with the Aeon rocket engine. They’ve test-fired it about a 100 times by now and are testing the first stage deployment system. With the pace they’re showing recently, they’ll be up in the air (and beyond) in no time.

Featured image courtesy of Relativity Space, via Forbes.