Johns Hopkins researchers have developed a new approach to 3D printing that combines the precision of additive manufacturing with the speed of traditional molding techniques. The method, called Hybrid Formative-Additive Manufacturing (HyFAM), was created by a team from the Department of Civil and Systems Engineering at the Whiting School of Engineering. Their research was recently published in Advanced Materials.

“Instead of viewing additive and formative manufacturing as competing methods, we had the idea to marry the two,” said Jochen Mueller, CaSE assistant professor and principal study author. “By combining the benefits of each, we created a new production method that also overcomes some of their major drawbacks.”

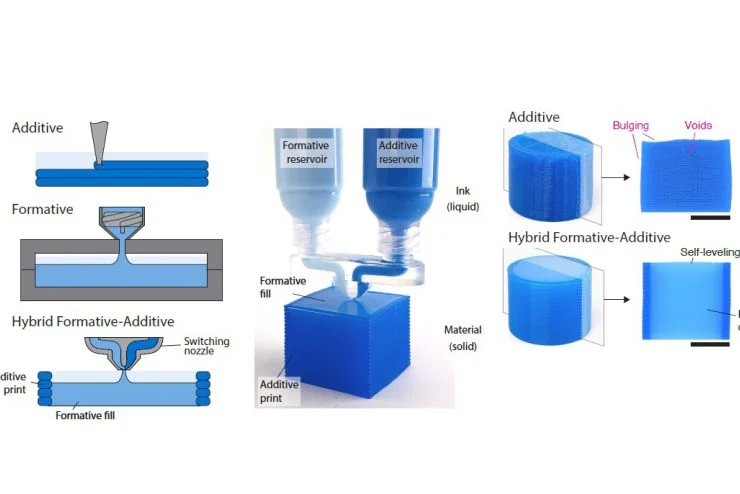

HyFAM works by using a casting-like process for bulk sections where fine detail isn’t necessary, while employing traditional 3D printing techniques for detailed areas like outer surfaces. This combination can make production up to 10 to 20 times faster for objects with significant cast-like fill, and approximately twice as fast for detail-heavy prints, according to Mueller. The method helps avoid the inefficiency of printing every part when only certain sections require precision.

The team has tested HyFAM with various materials including silicone, ceramics, metals, epoxy, cement, clay, and chocolate. The process required careful control of material flow and consistency to ensure even filling. It also addresses common 3D printing problems by helping bond printed sections together uniformly.

Nathan Brown, a doctoral candidate and first author of the paper, explained the advantage: “Additive manufacturing offers significant detail, but when you use a small nozzle to achieve it, the entire process slows down. This becomes a real hinderance in parts with large internal features and widely-varying feature sizes.”

The researchers note that HyFAM is particularly useful for mass customization scenarios where objects have both detailed and non-detailed sections. While not ideal for highly intricate uniform objects, the team plans to expand the method’s capabilities by experimenting with different material combinations to broaden potential applications in industries from construction to soft robotics.

Source: engineering.jhu.edu