Researchers at Heriot-Watt University working alongside collaborators from Carnegie-Mellon University and Argonne National Laboratory have published an article in Nature Communication detailing new findings into the formation of keyhole pores during LPBF printing of metals.

As we saw in this previous article which highlighted Argonne National Lab’s previous research into in-situ monitoring of keyhole cavity formation, the cavities are created when a surplus of laser energy is focused on a particular spot for too long, resulting in metal vaporizing and exiting the melt pool, leaving a small void (keyhole).

This results in porosity throughout the printed part which can result in stress concentrators, unpredictability in the part’s mechanical behavior under loads, and ultimately part failure.

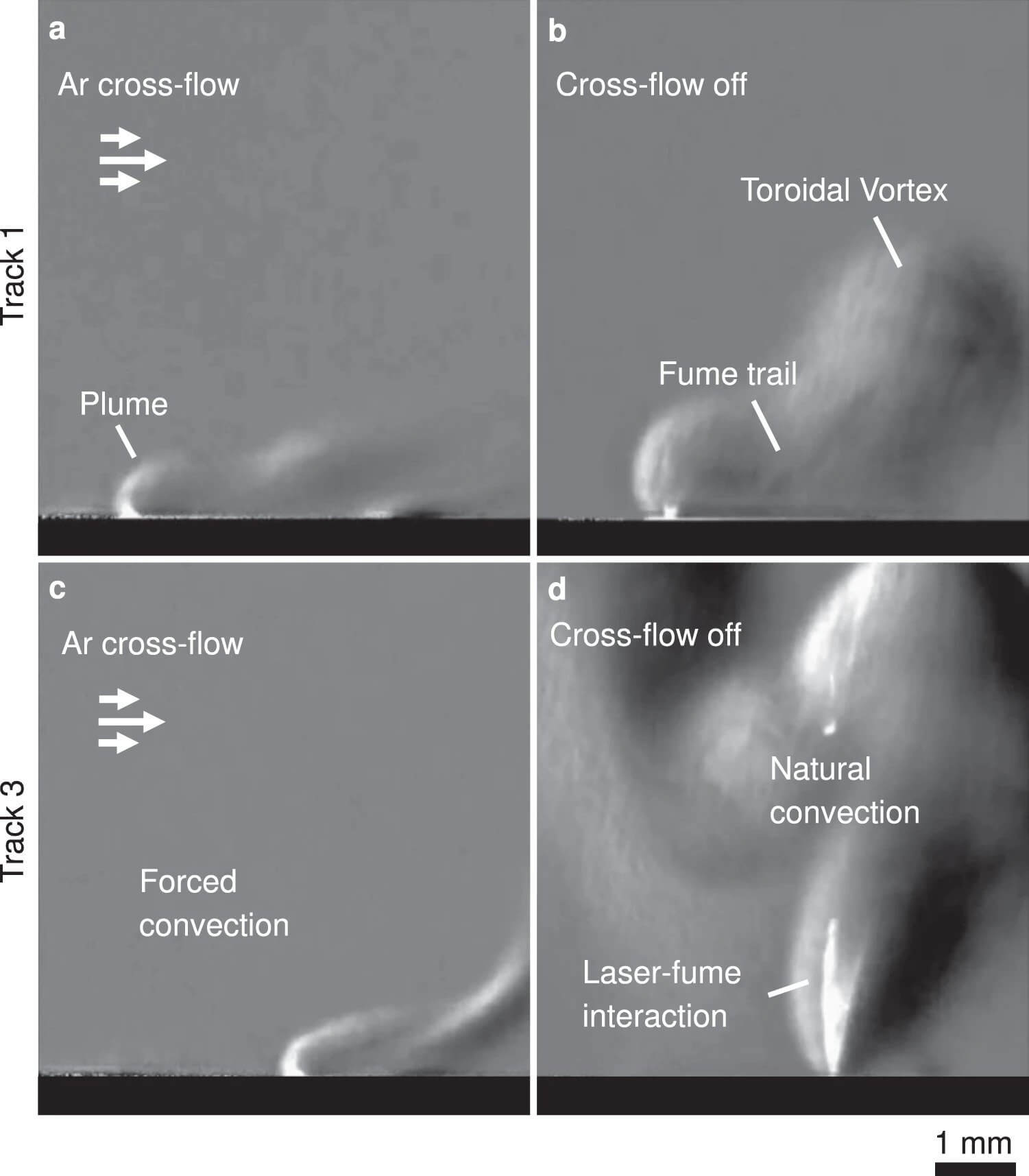

The new research shows the actual formation of these evaporation plumes and visualizes all of the phases of matter as they undergo transformation from solid to melt pool to vapor. This is achieved with simultaneous in-situ synchrotron x-ray and schlieren imaging, which you can see in the picture below.

The image sequence above shows the time evolution of the depression formation and the vapor plume behavior under a stationary laser spot with a 1/e^2 diameter of 84 µm, for substrate only (no powder).

“During the additive manufacturing process, the application of a high-powered laser to metal will result in a small pool of liquid metal as the particles fuse together,” said Dr Ioannis Bitharas, a research associate at Heriot-Watt.

“During this stage, a minute amount of metal evaporates and presses against the liquid, creating a cavity at the center of the melt pool. This cavity, often referred to as a keyhole, can become unstable and collapse, leading to pores in the material. At the same time, the vapor shoots upwards from the keyhole, forming a plume, which interacts with the particles and can potentially disturb the spread layer.”

“Such events create tiny imperfections scattered throughout the component and, consequently, an unacceptable level of material porosity to many manufacturers. The images we have captured provide, for the first time, a complete picture of such interactions and we can now tell with certainty what is happening.”

The research showed the interaction between plume dynamics and the depression formation. In short, a steady plume results in a more predictable (and therefore controllable) depression and reduced porosity in the part, while the unsteady plume results in a more unstable melt pool resulting in unpredictable depression formation and higher porosity (and weaker parts).

This process can be kept stable by varying printer parameters such as energy density and speed, and the research also examines the effects of atmosphere (convection vs forced convection) on the plume.

“We believe that this work will enable the creation of improved process monitoring and analytic tools that identify and prevent defects in the additive manufacturing of metals, said Professor Andrew Moore, head of the Optical Diagnostics group in the Institute of Photonics and Quantum Sciences at Heriot-Watt.”

“Additionally, it will underpin a more predictive class of multiphysics models which include atmospheric effects and powder motion, allowing accurate a priori calculations of process maps.”

If you’d like to read the article in full (open access) you can read it over at this link.