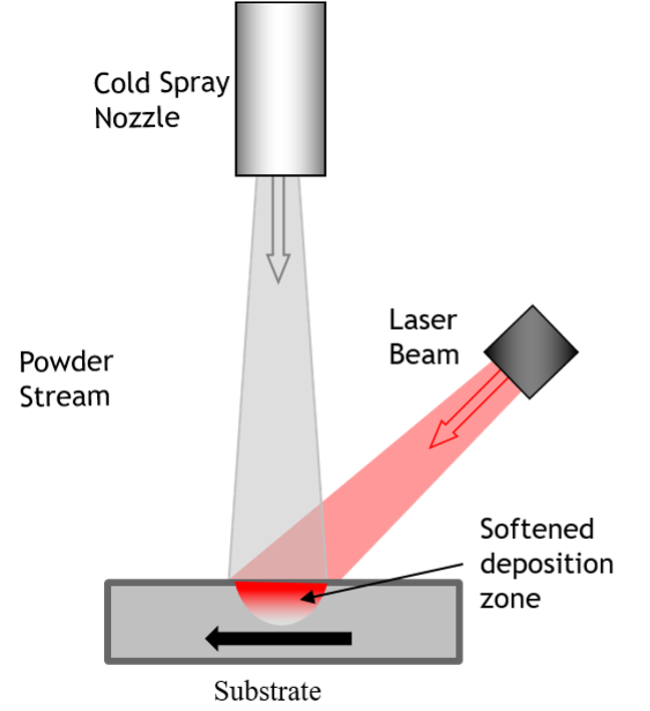

Researchers at the University of Cambridge’s Center for Industrial Photonics have developed a new additive manufacturing technique called laser-assisted cold spray (LACS). The process combines localized laser heating with a supersonic powder stream to deposit metals and cermets for building, coating, or repairing parts. This approach addresses the high-temperature and material limitations found in comparable techniques such as thermal spraying.

The development addresses a significant cost challenge in cold spray manufacturing. Traditional cold spray processes for high-strength materials like titanium and aluminum alloys require helium as a carrier gas, which costs approximately £80 per minute of operation. “The requirement for helium posed a significant challenge because of its cost, which is around £80 per minute of operation. Even state-of-the-art recycling efforts recovered only around 85% of the helium,” said Professor Bill O’Neill, who leads the research team.

LACS offers several technical advantages over conventional cold spray methods. The process enables deposition at lower particle velocities, which preserves the powder’s structure in the final coating. It also operates at lower gas temperatures of 400-700°C compared to up to 1,200°C for standard cold spray, reducing power consumption. Coatings can be applied at rates up to 10 kg per hour while maintaining the substrate below melting temperature to avoid distortion.

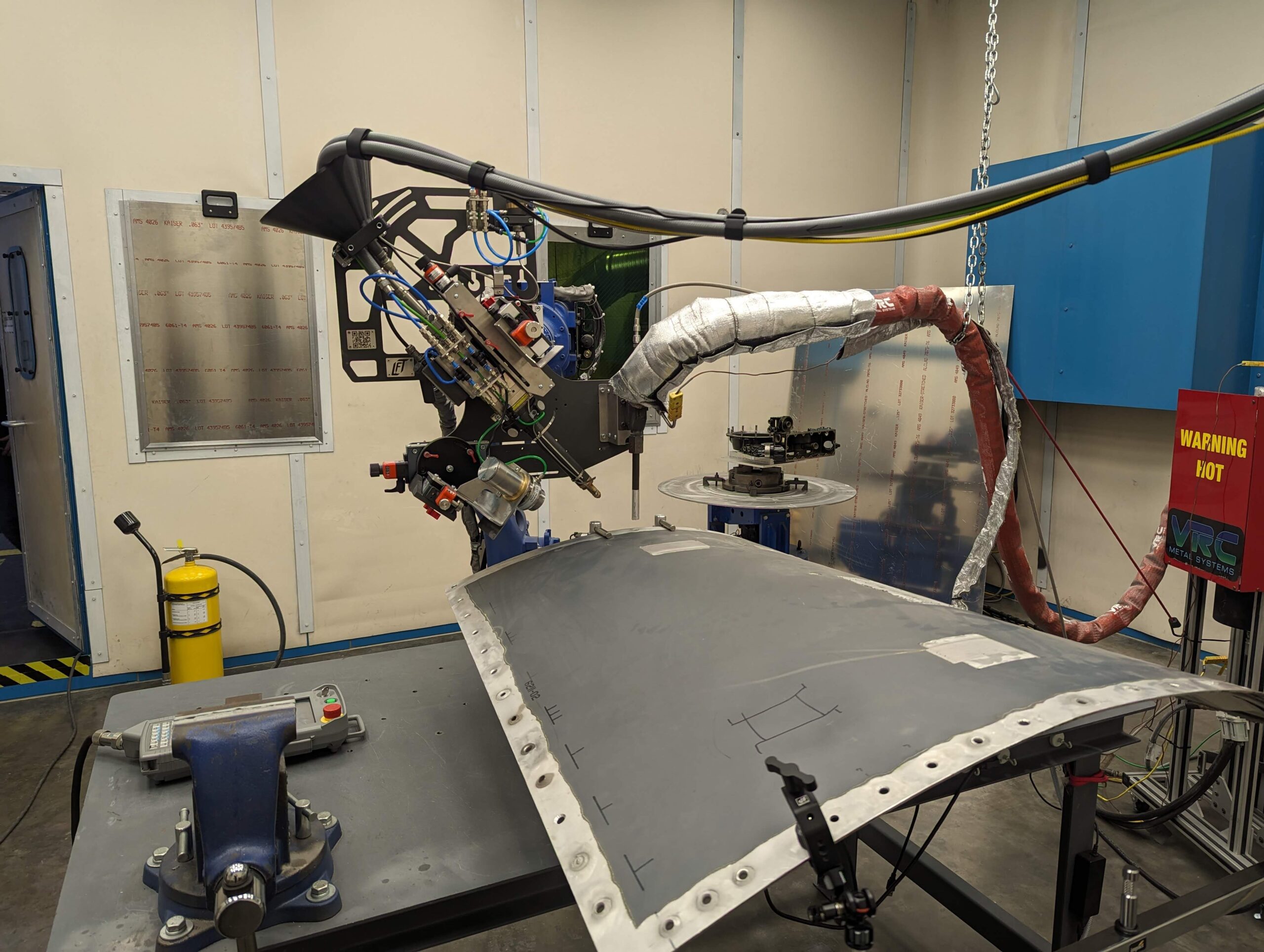

The aerospace industry represents a primary application area for LACS technology. The technique enables on-demand repair and manufacturing of aircraft components, potentially extending aircraft lifespans. Traditional storage of spare parts is costly and space-intensive, and once parts are depleted, aircraft can become unusable due to lack of replacement components. The global additive manufacturing market is projected to reach between $70 billion and $88 billion by 2030, with the UK currently holding approximately 7.6% of the global market.

The research team is working to enhance LACS capabilities for full 3D printing applications. Current limitations include minimal control over powder deposition shape, which restricts part-building applications while remaining suitable for coating work. “Currently, we have little control over the shape of deposition of the powder. This is not an issue for coatings but presents a significant restraint for part-building applications. Our next goal is to find a solution to this limitation, and we already have some very promising results,” said O’Neill.

Source: eng.cam.ac.uk