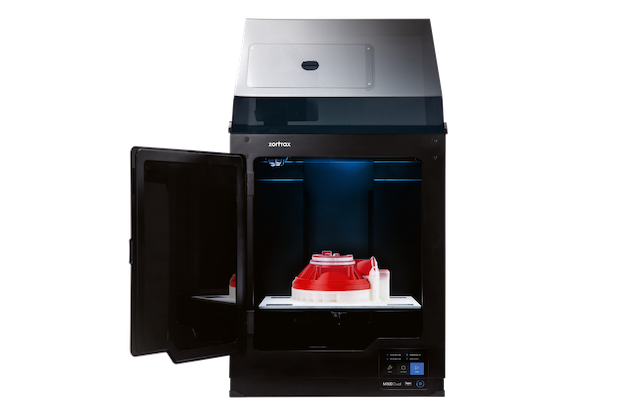

As a follow-up to their M300 Plus, Zortrax has just released the M300 Dual with dual extrusion capabilities. The company is billing it as a large-volume device, touting its ability to print with standard filaments and dissolvable filament as support simultaneously. This provides the M300 Dual with the ability to print intricate geometries not possible in previous iterations.

Zortrax will be releasing it in mid-2019, pricing it around €3,990. The company sees the M300 Dual as a device that offers ‘industry-standard’ printing in a desktop 3D printer format.

“The dual-extrusion system and large workspace allow industrial-standard detailed and complicated printing, while maintaining the characteristics of a desktop printer,” commented Rafal Tomasiak, CEO of Zortrax. “Our goal is to transfer the possibilities offered by industrial printing to smaller, more user-friendly devices. The new M300 Dual is another step in this direction. We have created a comprehensive system enabling users to work using Zortrax devices.”

New Additions

As a part of the M300 series, the Dual adds a lot to the table while building on what came previously. Aside from the double extrusion technology, it also brings in a considerable build volume. Moreover, it uses what volume it has very efficiently thanks to the LPD Plus technology. The soluble support allows users to stack batches of parts up one on top of the other. This way the machine uses the entire build volume (265 x 265 x 300 mm) for each working cycle.

As one would anticipate, all Zortrax materials are compatible with it, along with a range of 3rd party filaments. It also brings in better jam detection using a built-in camera, that monitors the consistency and quality of prints. In terms of run-outs or jams, the system will automatically notify the user and pause the print. It even uses two sensors to detect jams or inconsistencies. Similarly, the blackout response system keeps the M300 Dual operational using extra capacitors till the print progress saves, ensuring a smooth return to operations in the event of power outages.

The build-platform in the M300 Dual automatically calibrates itself with a ‘capacitive displacement sensor’. Effectively, the sensor performs high-resolution measurements of the position of any conductive or nonconductive target with only the press of a button. Thus, it can calibrate both perforated and glass build-platforms automatically. The company even claims that users could test it with any material-type build platform and it would still work.

Featured images and video courtesy of Zortrax.