Space hardware needs a lot of panels. Be it for rocket bodies, satellite structures, and even space stations.

In particular, space hardware needs strong, stiff and lightweight panels. This can be in the form of honeycomb structures, or in the case of this article, in isogrid panels.

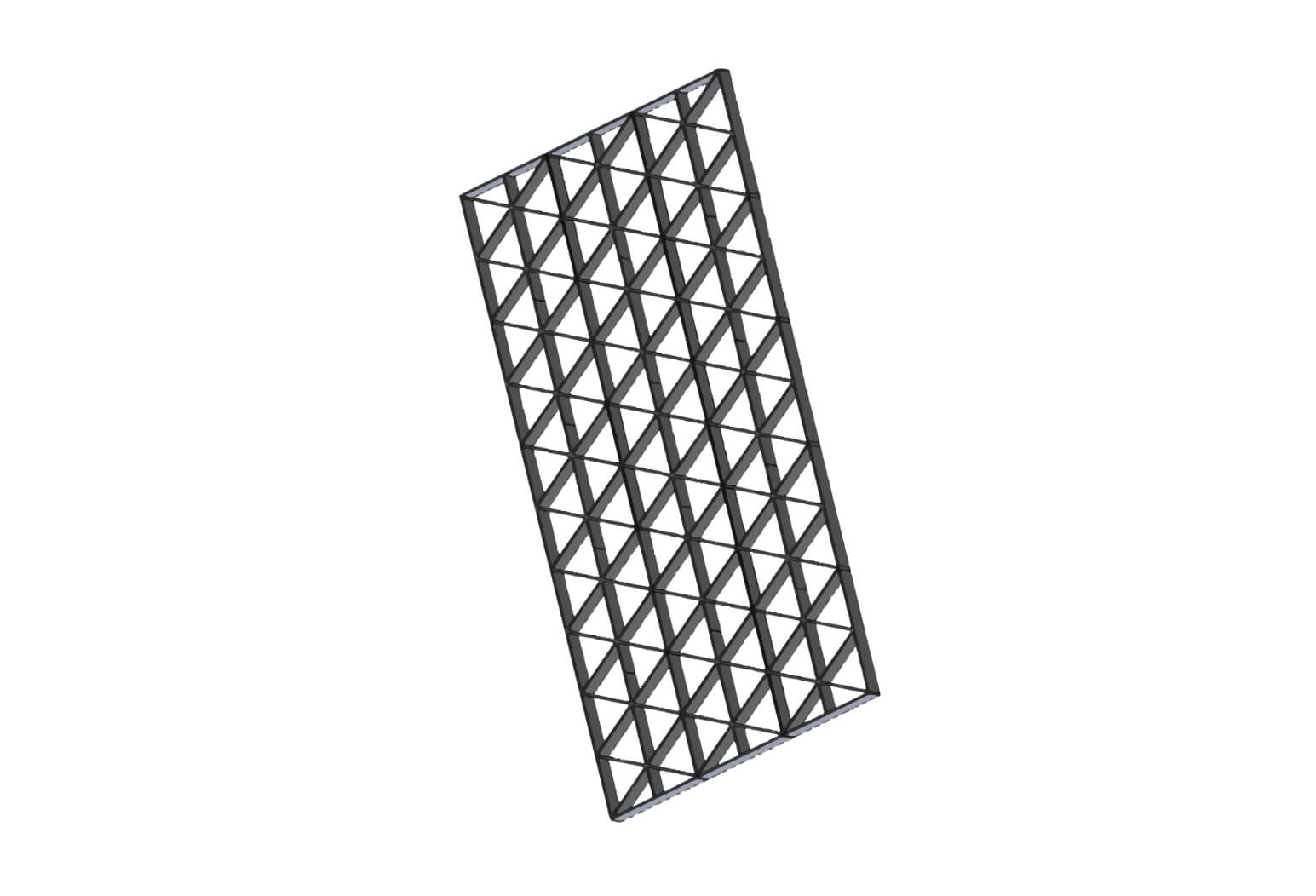

An isogrid panel is like a solid panel, but thinner, and with a pattern of stiffeners on the face. It maintains strength and stiffness while reducing weight.

You can see a traditional isogrid panel in the image below. Typically they are fabricated by CNC machining, and aluminium is often preferred due to its mechanical properties, and cost.

So how does one improve on metal isogrid design? Why with composites of course. And what is better than a composite isogrid? A 3D printed one, naturally!

And that is why Idaho-based company Continuous Composites has been selected by NASA’s Small Business Innovation Research (SBIR) Program – to manufacture open isogrid structures with a low CTE, or coefficient of thermal expansion.

Space is a harsh mistress, to paraphrase Heinlein, and contains all kinds of hazards punishing to hardware and biology. In orbit, one hazard is the fluctuation of temperature as a body moves from daylight into the shadow of the body it is orbiting, for example a satellite orbiting the Earth.

As a body heats and cools, it expands and contracts, and the scale of the expansion is determined by the CTE. As things expand, especially in an assembly, it can cause stresses and strains on the structure, and if it isn’t managed it can have undesirable consequences. Expensive ones. You can’t generally fix things once they are in space, so they have to be engineered with the utmost reliability.

Continuous Composites in particular are producing what is called an “open isogrid”, for reasons obvious in the image below.

While typical isogrids are monolithic and are manufactured with the panel and the grid, an open isogrid like the picture above can be placed onto an existing panel, regardless of the shape, be it flat, cylindrical or a more complex curve.

With the funding from NASA, Continuous Composites will use their patented technology to robotically place individual carbon fiber tows into the form of an isogrid, specifically a rectangular one in this instance measuring 1.6ft x 3.3ft.

“Given my background in composite design for space applications, I’m excited to demonstrate our unique fiber steering capabilities for this NASA project,” said John Brendel, Application Engineer and technical POC on this NASA SBIR.

“This printed isogrid will have very little to zero CTE which is the goal for these types of space structures. This contract builds upon the work we have been doing in the DoD and commercial aerospace sector, and we’re excited to introduce our unique capabilities to the space industry.”

The Continuous Composites process (named CF3D) begins with a continuous dry fiber that is impregnated in situ with a tailorable, snap curing thermosetting resin delivered by the end effector (robotic toolhead). You can see the robot doing its thing in the picture above.

If you’d like to know more about the applications of CF3D technology, you can head on over to their website at this link.