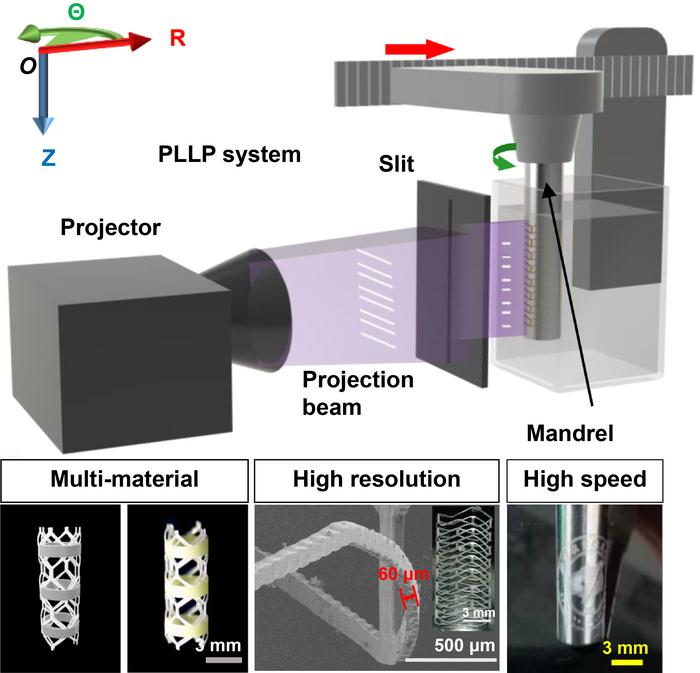

Beihang University researchers have developed a new 3D printing technology dubbed “Polar-coordinate Line-projection Light-curing Production” (PLLP) system. The work, published in the International Journal of Extreme Manufacturing, offers advantages over traditional Cartesian coordinate-based 3D printing systems.

3D printing methods using Cartesian coordinates have encountered challenges in fabricating intricate tubular structures. However, the PLLP system offers a novel approach.

Unlike its predecessors, PLLP operates on a polar coordinate system, utilizing rotation and retraction mechanisms to simplify manufacturing. By eliminating the need for supporting structures, PLLP achieves precise and rapid printing of ultra-thin tubular components, with a minimum wall thickness of 50 micrometers.

Moreover, PLLP’s versatility extends beyond rigid materials, as demonstrated by its successful utilization in printing hydrogel structures—a feat previously unattainable with conventional techniques.

“Smooth ultra-thin tubular structures are common in biomedical engineering,” said Jiebo Li, Professor in School of Biological Science and Medical Engineering, Beihang University.

“The biggest advantage for PLLP is that one can rapidly fabricate smooth-surfaced tubular multi-material structures. This method is particularly beneficial for the swift customization of tubular grafts as well as the manufacturing of tubular components in other fields.”

As research progresses, the team at Beihang University aims to further enhance PLLP’s capabilities, focusing on improving printing speed and resolution. Beyond biomedical fabrication, the researchers point out that it holds potential for other domains, such as dentistry and aerospace.

You can read the full paper, titled “Polar-coordinate line-projection light-curing continuous 3D printing for tubular structures” at this link.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.