French researchers have developed a new optimization framework for 3D printed concrete that reduces material usage by up to 25% while maintaining structural integrity. The study, published in Automation in Construction and led by Dr. Romain Mesnil at École des Ponts ParisTech, focuses on variable layer thickness achieved through adjusting robot velocity during printing. The approach marks a departure from conventional 3D concrete printing methods that typically use uniform wall thickness.

“This research shows that by leveraging the capabilities of robotic printing, we can move beyond constant layer designs and make data-driven decisions about where material is truly needed,” said Dr. Mesnil. “It’s a step-change toward greener, smarter construction.”

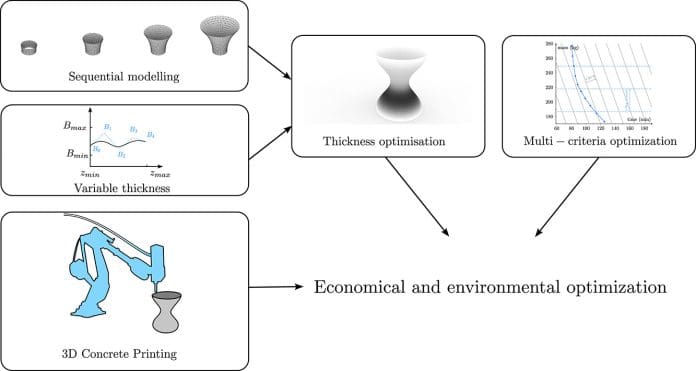

The team’s method employs a lightweight finite element analysis approach using shell elements, which reduces computation time while maintaining accuracy. Their framework includes a parametric optimization routine connecting process parameters with material deposition, Bezier splines to control thickness gradients, and integrated numerical analysis to ensure mechanical reliability. The researchers validated their approach through full-scale printing experiments on complex shapes using a robotic arm system from XTreeE.

Testing showed variable thickness printing achieved up to 25% reduction in concrete usage and 20% decrease in cost compared to conventional methods. An hourglass-shaped test structure demonstrated particularly strong results, with variable thickness designs outperforming constant thickness in material efficiency, time, and cost metrics.

The optimization framework offers manufacturers potential benefits including reduced carbon emissions, faster print times, and flexibility in balancing productivity with environmental performance. To facilitate adoption, the researchers developed a design-to-print workflow compatible with common parametric design software Grasshopper and Karamba, allowing for integration into existing design environments.

Source: pbctoday.co.uk