Northwestern University’s Materials Science and Engineering department has implemented a new hands-on approach to teaching soft materials concepts. Professor Ryan Truby’s MAT_SCI 331: Soft Materials course now features 3D Printing Resin Design Labs, where students create and optimize their own printing materials. Student teams work with a dozen desktop resin 3D printers to develop custom formulations for specific applications.

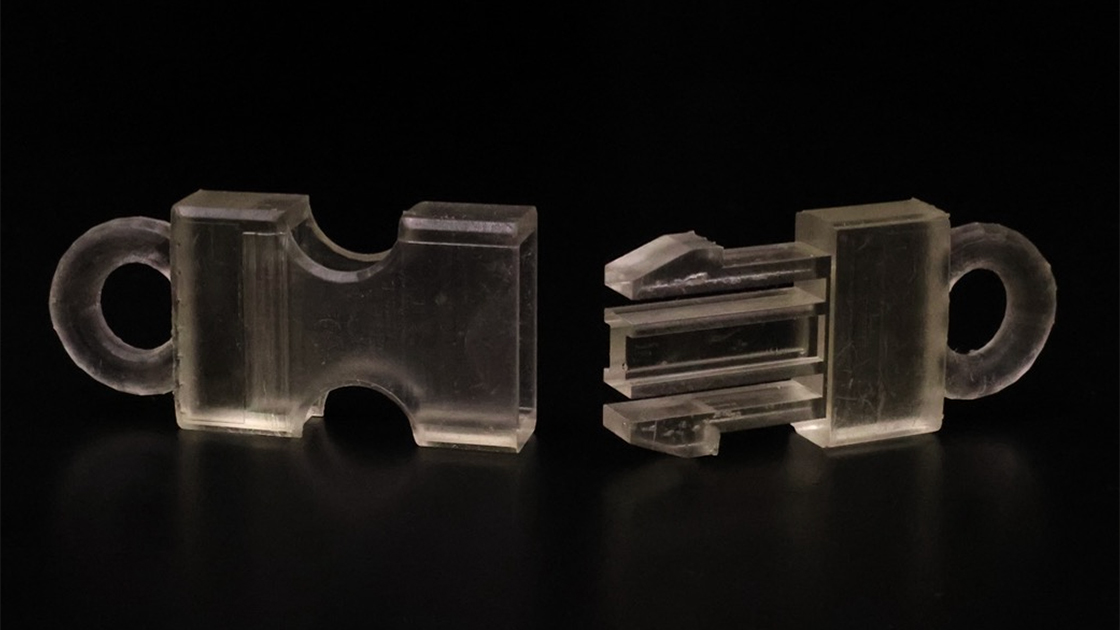

The redesigned course challenges students to produce functional plastic buckles capable of withstanding heavy loads. Participants progress through six intensive labs focusing on 3D printing, materials characterization, and mechanical testing. This approach integrates theoretical concepts with practical application, allowing students to experience firsthand how modifying resin formulations affects printed part performance.

“3D printing as a technology requires interdisciplinary materials science and engineering knowledge, spanning organic chemistry and polymer physics to rheology and mechanics,” said Truby, who holds positions as June and Donald Brewer Junior Professor and assistant professor of materials science and engineering and of mechanical engineering. The initiative received support through Truby’s 2023-24 Searle Fellowship and a 2023 Murphy Society Award shared with Professor Jonathan Emery.

Students report positive experiences with the hands-on format. “The class greatly surpassed my expectations, offering far more hands-on experience than anticipated,” said third-year undergraduate Julia Wiater. Fellow student Hayden Williams added, “I felt I had a large amount of control, which was nice as most other lab-based courses focus on one very specific test or experiment.”

Source: mccormick.northwestern.edu