Researchers at Western University have released SpecOptiBlend, an open-source software package that enables the creation of custom-colored materials from recycled plastic waste. Published in Advanced Manufacturing, the new tool allows users to match specific color requirements when converting waste plastic into 3D printing filament. The software uses spectral reflectance data and color mixing techniques to transform recycled materials into precise color formulations.

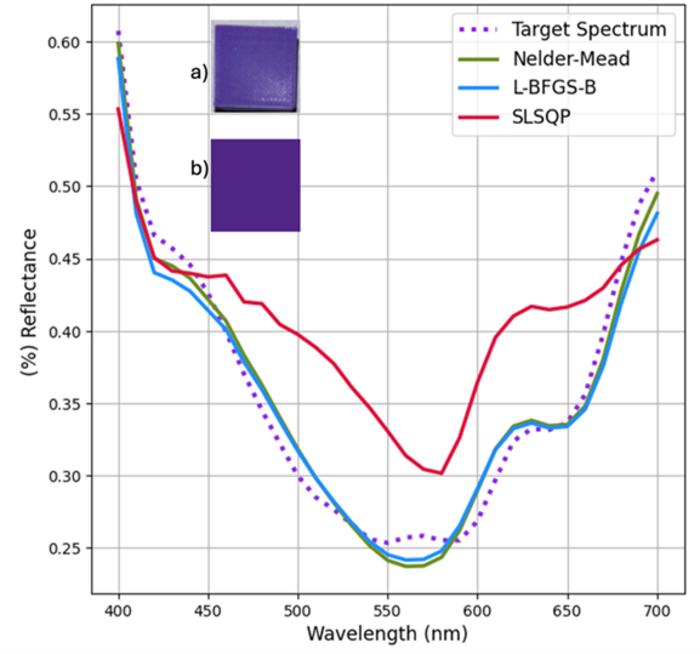

The development addresses a previous limitation in distributed recycling and additive manufacturing (DRAM), where users were restricted to original waste plastic colors or basic mixed shades. According to Professor Joshua Pearce, Thompson Chair in Innovation at Western University, the team successfully matched specific colors like “Western’s regal purple” and the pink petals from a LEGO wildflower set. The software employs various optimization techniques to achieve accurate color matching.

“We have pushed plastic recycling to the next level, because now you can get custom colors for your 3D prints that are not even available on the market,” explains Pearce. “In the past you either had to be happy with the colors your waste plastic came in or mix them together and get boring grey.”

The research team tested three optimization methods, with the Nelder-Mead approach providing the best balance between color accuracy and root mean square measurements. Their paper, “Creating custom 3D printing material colors using optical modeling of waste plastic,” is now published in Advanced Manufacturing and the software is freely available for public use.

Source: eurekalert.org