Oak Ridge National Laboratory has been developing a framework for the inspection of 3D printed metal parts utilizing artificial intelligence combined with X-ray computed tomography (a.k.a CT). The methodology will increase the speed of such non-destructive testing (NDT) and material characterization, as well as the accuracy of the results.

As we have reported previously, ORNL has already been busy developing AI-assisted methods of fault detection that can be applied while a metal part is being printed. By developing new means of inspecting parts after they have been printed, the laboratory has now added an extra stage of quality control to manufacturers’ QC toolbox.

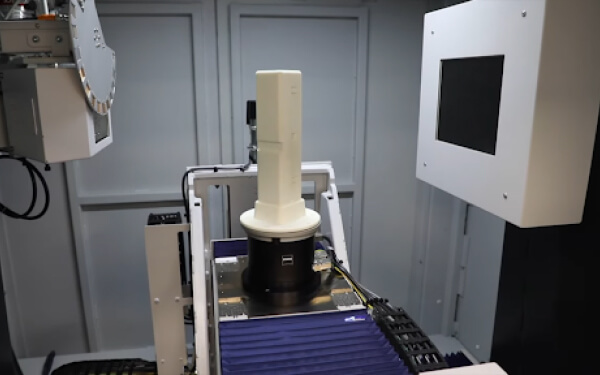

X-ray CT scanning is an NDT method that builds up a 3D image from X-ray scans as the part is rotated on a platform. The method is used to assess the density of a part, and can display any defects inside the part without having to destroy the sample to see inside (hence the term “non-destructive”).

While X-ray CT has been used on small batches and in research institutes for the analysis of 3D printed parts, it has been difficult to scale up for mass production parts due to the slow scanning speed and lack of accuracy in the method. This lack of accuracy is the result of lower-energy X-rays being absorbed by certain areas of metal, which can create inaccuracies in the resulting image. The errors can be compensated for manually by a technician, but this process is time consuming.

To combat this, the researchers at ORNL have employed the use of Deep Learning that automatically reconstructs the images more accurately, thus alleviating the manual elements of the analysis that would have previously been the job of a technician.

As with much of Deep Learning, the results are only as good as the training data used to train the AI. In the case of scanning metal with X-rays, gathering this data is also extremely time consuming, requireming real-life experimentation to provide the training data in the first place.

The ORNL team has reduced the dependency on expensive experimental data by employing a generative adversarial network, or “GAN” for short. The GAN is used to synthetically create a realistic-looking data set for training a neural network with the aid of CAD models and physics-based simulation.

With the aid of the GAN, the researchers have been able to reduce the time per scan by a factor of 6.

“The scan speed reduces costs significantly,” said Amir Ziabari, ORNL lead researcher. “And the quality is higher, so the post-processing analysis becomes much simpler.”

“People don’t use novel materials because they don’t know the best printing parameters. Now, if you can characterize these materials so quickly and optimize the parameters, that would help move these novel materials into additive manufacturing.”

You can see the process at work in the video below.

The method is already being incorporated into software used by ZEISS, who are using their own machines at ORNL’s AM proving ground.

“With this, we can inspect every single part coming out of 3D-printing machines,” said Pradeep Bhattad, ZEISS business development manager for additive manufacturing.

“If I can very rapidly inspect the whole part in a very cost-effective way, then we have 100% confidence. We are partnering with ORNL to make CT an accessible and reliable industry inspection tool.”

You can read our previous article on ORNL’s work on AI-assisted in-situ fault detection over at the link below.