Oak Ridge National Laboratory has recently published a paper in Nature Communications detailing their most recent 3D printing achievement in the field of binder jetting.

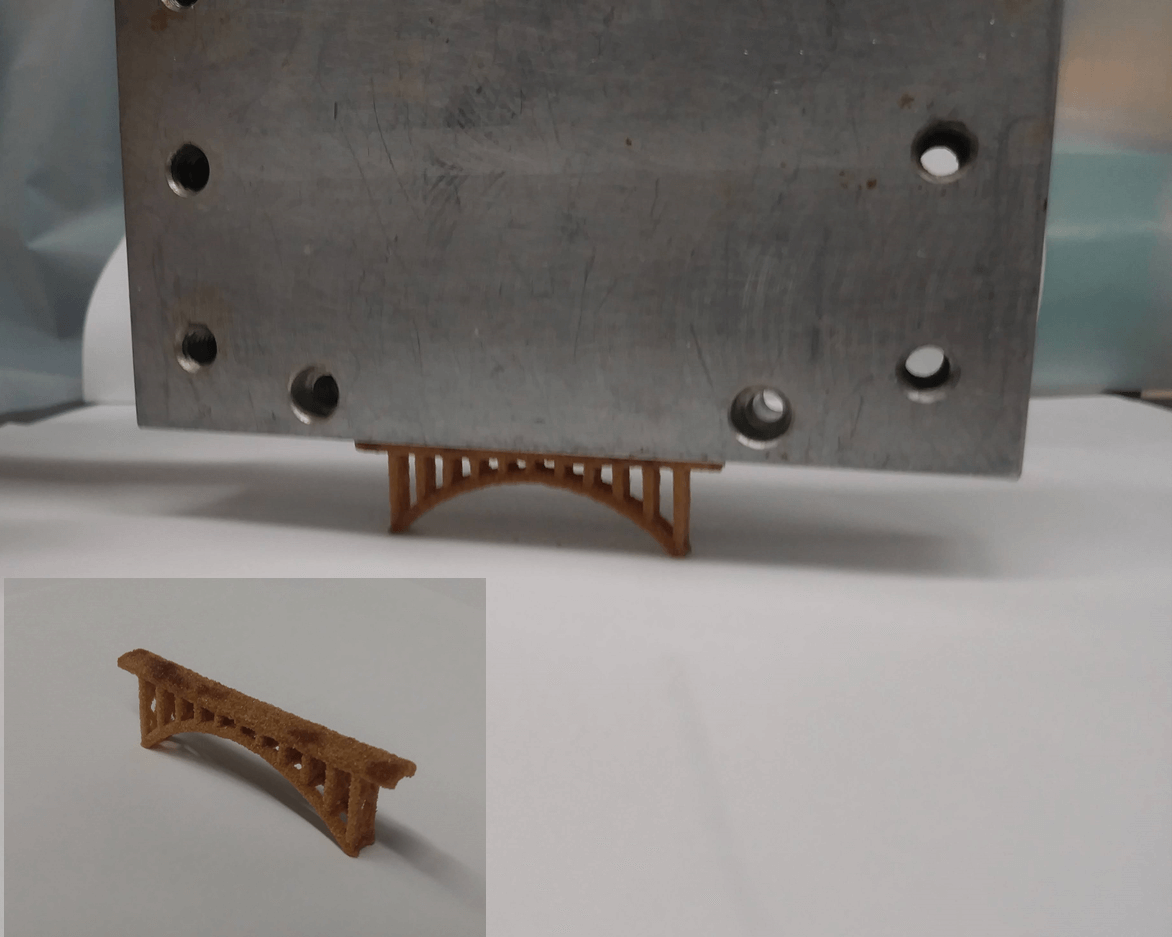

The latest discovery demonstrates a rapid and cost effective method of printing silica sand structures with the use of a custom-made polymer as the binder. The structures so far have proven capable of supporting 300x their own weight, which according to ORNL, is equivalent to standing twelve Empire State Buildings on the Brooklyn Bridge.

Infact, the structure in question was indeed a miniature bridge, and you can see it supporting a huge lump of metal in the image below.

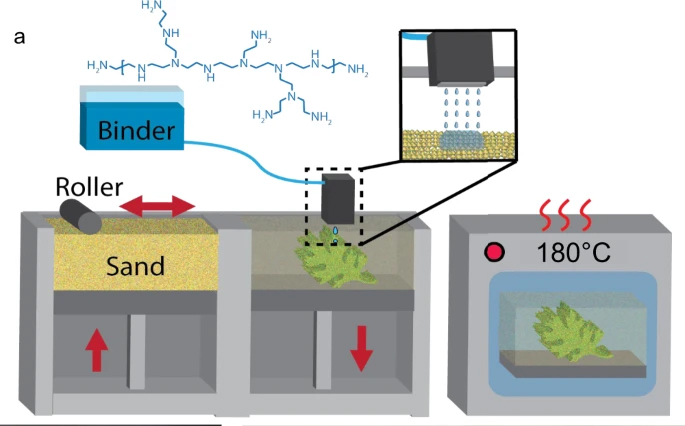

Typically for binder jetting applications a polymer is used as the resin to bind the matter together. The new polymer known as polyethyleneimine (PEI) was tailor made for the application and has been demonstrated to double the strength of the printed part when compared to usual binders.

“Few polymers are suited to serve as a binder for this application,” said Tomonori Saito, a researcher on the project at ORNL.

“We were looking for specific properties, such as solubility, that would give us the best result. Our key finding was in the unique molecular structure of our PEI binder that makes it reactive with cyanoacrylate to achieve exceptional strength.”

Typically, parts made with binder jetting are porous, and the pores are filled afterwards with cyanoacrylate (super glue) to increase the density of the part and to add strength. This step increases the part strength an additional eight times on top of the already doubled strength from the PEI, and this additional increase in strength comes from how the PEI reacts with the glue.

Specifically, the new sand material has a textural strength of 6.28 MPa compared with that of the conventional binder, making it stronger than unreinforced concrete (~4.5 MPa) in flexural loading.

So, why use sand at all?

Sand is used because sand is super-cheap and abundant, and it is used in industry, especially for tooling for composite manufacturing. Sand also has great thermal properties and does not expand when exposed to composite curing temperatures, therefore allowing manufacturers to maintain dimensional stability of the sand-based tooling even when heated up.

And because the PEI is water-soluble, manufacturing engineers and technicians can simply remove the part once it has been cured, wash, and go! The sand core will dissolve, reducing the labour costs associated with mold/tooling removal.

“To ensure accuracy in tooling parts, you need a material that does not change shape during the process, which is why silica sand has been promising. The challenge has been to overcome structural weakness in sand parts,” said Dustin Gilmer, a University of Tennessee Bredesen Center student and the study’s lead author.

“Our high-strength polymer sand composite elevates the complexity of parts that can be made with binder jetting methods, enabling more intricate geometries, and widens applications for manufacturing, tooling, and construction.”

If you are wondering if this new material will be available anytime soon, then you are in luck, as the material has been licensed by ExOne for use on their machines.

For more details on the super-strong sand material and its polymer binder, you can read the article over at the open access link right here.