Scientists at Oak Ridge National Laboratory have pioneered a new approach dubbed the “Frankenstein design” to overcome challenges in 3D printing neutron collimators. These vital components, crucial for neutron scattering experiments, were previously hindered by the limitations of traditional manufacturing methods. Neutron collimators serve to filter out unwanted neutrons, ensuring accurate data collection during experiments.

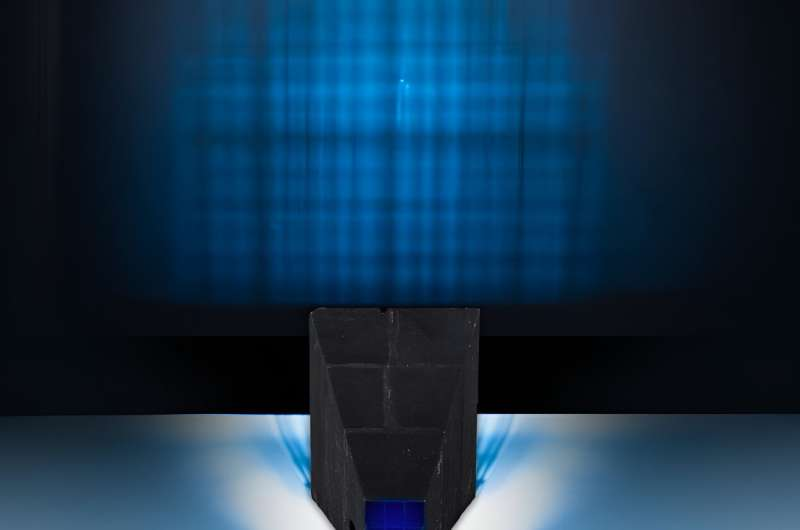

By utilizing additive manufacturing techniques such as binder jetting, the team successfully printed multiple smaller parts and manually assembled them into complete collimators. This approach not only addressed issues of precision but also allowed for the customization of collimator designs to suit specific experimental requirements.

The innovative “Frankenstein design” incorporates alternate-blade configurations, optimizing collimator performance while mitigating size-related printing limitations. Advanced computational simulations were employed to refine the design, streamlining the production process and ensuring optimal functionality.

Experimental validation on the Spallation Neutron and Pressure beamline demonstrated the efficacy of the 3D printed collimators, showcasing a significant increase in sample signal relative to unwanted scatter. The success of this endeavor highlights the transformative potential of combining modeling and advanced manufacturing techniques in advancing neutron science.

“To demonstrate the viability of using custom-built, 3D-printed collimators, we decided to use a very small sample contained in a diamond anvil cell—a high-pressure chamber that uses diamonds to squeeze materials”. Said Bianca Haberl, the study’s corresponding author and a neutron scattering scientist at SNS.

“Some of these cells are so complex and strong that they are capable of producing pressures approaching those at the center of the Earth. In fact, high-pressure cells are some of the most complex environments used in neutron experiments, so it is a real challenge to filter out the huge amount of unwanted cell scatter they produce.”

Moving forward, further refinements in manufacturing quality control and alignment procedures promise to enhance the precision and effectiveness of neutron scattering instrumentation. By breaking new ground in customizing collimator designs, this research sets a precedent for future innovations in neutron science and beyond.

Source: ornl.gov

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.