Robotic hands have long struggled to match the dexterity and versatility of their human counterparts. While conventional industrial robots rely on simple grippers or suction cups for manipulation tasks, these solutions fall short when it comes to handling a wide range of objects with precision and sensitivity.

In a bid to bridge this gap, a team of researchers from ETH Zurich and Nanyang Technological University has developed a new solution: a sensorized soft skin for robotic hands. With this approach, the researchers aim to equip robotic hands with tactile sensing capabilities akin to those found in human hands.

Human hands possess a remarkable ability to perceive and manipulate objects, thanks to their intricate structure and embedded tactile sensors. While robots have made strides in mimicking human-like manipulation skills using visual feedback, tactile sensing has been identified as a crucial component for enhancing robotic capabilities further.

Conventional robotic grippers often lack the structural complexity and soft properties necessary for delicate object manipulation. To address this limitation, the research team focused on developing a soft skin that could envelop robotic hands, providing joint protection and increasing contact area for improved grip.

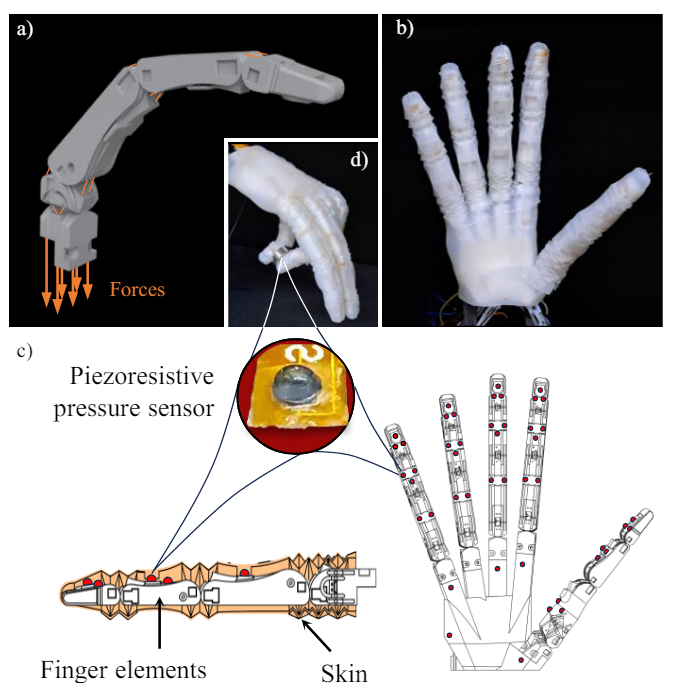

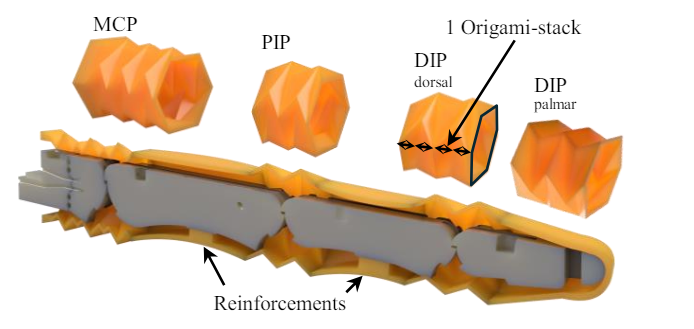

Using advanced techniques such as multi-material 3D printing and origami-inspired designs, the researchers were able to prototype complex skin geometries that maintained flexibility and durability. By casting the final skin design in silicone, they ensured a smooth and robust covering for the robotic hand.

Central to the project was the integration of piezoresistive pressure sensors within the soft skin. Strategically placed on key contact areas of the robotic hand, these sensors enable the detection of object grasps and assessment of grip strength. This sensorized feedback system mimics the proprioceptive abilities of human hands, allowing the robotic hand to interact more effectively with its environment.

To assess the effectiveness of their solution, the research team conducted a series of dynamic and static tests. Results showed significant improvements in the range of motion and grip strength of the robotic hand when equipped with the sensorized soft skin compared to traditional setups.

The development of sensorized soft skin for robotic hands represents a huge step forward in advancing the field of robotics. Not only does it enhance the dexterity and versatility of robotic manipulation, but it also opens doors to more sophisticated human-robot interactions in various domains, from manufacturing to healthcare.

You can read the full research paper, titled “Sensorized Soft Skin for Dexterous Robotic Hands” over at this link.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.