Researchers have demonstrated the printing of a multi-component part onto the tip of an optical fiber, as revealed in the latest Optics Letters journal.

Just last week we saw how researchers had successfully 3D printed optical fibers capable of temperature and strain sensing. In this article, we will see how engineers are also attempting to reduce the size of traditionally bulky optical devices with small-scale additive manufacturing.

Read on to know more.

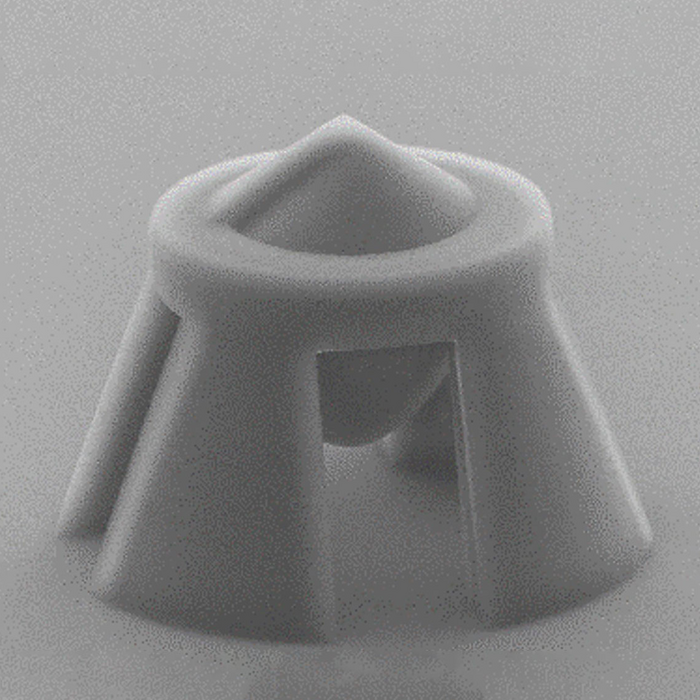

The researchers from Soreq Nuclear Research Center in Israel utilized two-photon polymerization to print the miniscule device, which you can see in the image above.

Using their off-the-shelf 3D printer and an optical grade photopolymer resin, they were able to print an optical device measuring just 110 microns in height and 60 microns in diameter on the end of a single mode optical fiber.

The multi-component device includes a parabolic lens for light collimation and a helical lens that twists the light into Bessel beam.

Bessel Beam

A Bessel beam is a type of light propagation that does not diffract. The light distribution of a Bessel beam maintains a tight focus with high irradiance over great distances. Its amplitude is described by a Bessel function, hence the name. These types of beams have applications in certain types of microscopy, and other medical imaging techniques, as the beam is capable of producing higher quality images as it doesn’t diffract (spread out) at depths, unlike normal beams.

“The ability to create a Bessel beam directly from an optical fiber could be used for particle manipulation or fiber-integrated stimulated emission depletion (STED) microscopy, a technique that produces super-resolution images,” said Shlomi Lightman, research lead at Soreq Nuclear Research Center.

“Our fabrication method could also be used to upgrade an inexpensive lens to a higher quality smart lens by printing a smart small structure on it.”

“When light comes out of the fiber, large bulky optical elements are typically used to route it to the next location. Our approach minimizes both the size and cost for this process by integrating the routing process into the fiber itself.”

Cost Effective Microscope Optics

The component itself was printed in less than 5 minutes, and the cost for both the optical fiber and printed component came in at under $100 USD, meaning a decrease in cost in the region of one order of magnitude compared to traditionally manufactured microscope objective lenses of comparable functionality.

The project was not without challenges however, as fabricating optical devices at this scale requires the utmost precision in 3D printing.

“We were able to overcome this hurdle by performing highly accurate 2D and 3D simulations before we began the fabrication process,” said Lightman. “In addition, we had to carefully think about how to integrate the optical elements with each other and then align that with the fiber core.”

After fabrication the team tested the optics and found that the low diffraction of the light beam was suitable enough for their STED microscopy requirements. In addition, it was found that despite being made from a polymer, the printed device was capable of allowing relatively high powered light though it – up to 10 MW/cm2 before the device failed.

The researchers plan to reduce the amount of polymer in the device to see if this can increase the power rating.

You can find the full paper, titled “Vortex-Bessel beam generation by 3D direct printing of an integrated multi-optical element on a fiber tip” in the Optics Letters journal, at this link.