Researchers at the Technical University of Vienna have just cracked the code on advanced light curing. The team has developed a method for printing tough photopolymers using EVS (ester‐activated vinyl sulfonate ester). As a result, they claim the eventual material is far more suitable for 3D printing, biomedicine and microelectronics.

Robert Liska is leading the research team. He has long been working with polymers, 3D printing and light-curing. His team’s work here presents a new way of decreasing chain link lengths during the polymerization process, which results in fewer cracks and precise shrinkage in the inner structure. The addition of EVS allows for the usage of methacrylate-based photopolymers without inhibiting the curing process.

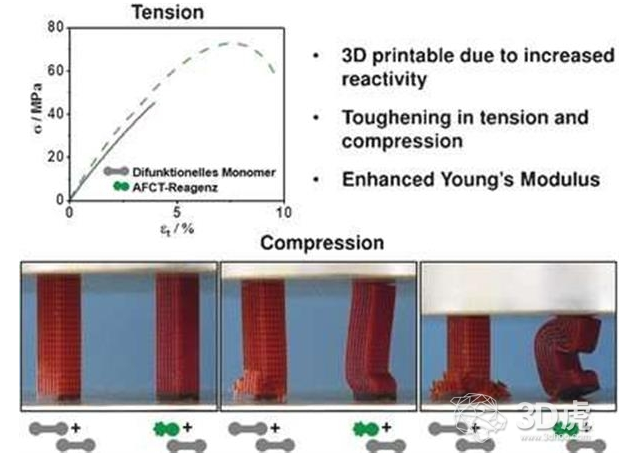

The researcher printed two versions of a scaffold: one with EVS and a control scaffold without it. As one might imagine, the former was solid and the latter much more brittle. The material had individual layers with a thickness of 50 µm and was homogenous, solid but elastic and impact resistant with high tensile strength.

Better Photopolymerisation

While the new method also works in a similar manner to regular light-curing, the presence of EVS makes a crucial difference. Light-curing operates with radical chain polymerization, using light to split an initiators into radicals. These then react to the monomer’s double bonds in the vinyl group (for example C=C) and form a new radical. The new radical becomes the starting point of a polymer network that builds by attacking other monomers.

However, longer irradiation phases lead to weaker bonds that are longer but develop shrinkage cracks. The EVS, on the other hand, acts as a buffer, which takes on the attacks instead of the monomers. As a result, it forms an intermediate and terminates the change making it more solid. The shorter chains remain mobile longer and thus reduce the danger of shrinkage cracks during curing significantly.

The researchers measured the characteristics of the new photopolymers with laser flash photolysis, theoretical calculations, and photoreactor studies. They found that the final photopolymer networks exhibited improved mechanical performance. Other chain transfer agents had significant downsides compared to EVS. Namely, they inhibit polymerization whereas EVS doesn’t because it forms a stable intermediate.

The abstract for the study is available here. The original study can be found in the journal Angewandte Chemie.