If you have ever wondered if your 3D printer can make you a sandwich and fold your shirts then you’ll be pleased to know that a team of university researchers have been grappling with this very problem, so you don’t have to.

The researchers have successfully shown the use of 3D printer heads as robotic actuators, as well as using that same print head to print, de-support and assemble components in a production line.

Behold, the Functograph!

Sandwich

The researchers (Yuto Kuroki and Keita Watanabe) from Meiji University, in Japan, have designed a modification system that turns a standard prusa-type printer into a self assembling factory production line, capable of performing a variety of pick-and-place and other automated assembly-type tasks.

First they designed the components for their Rube Goldberg-esque contraption, then they printed the components on a DIY 3D printer.

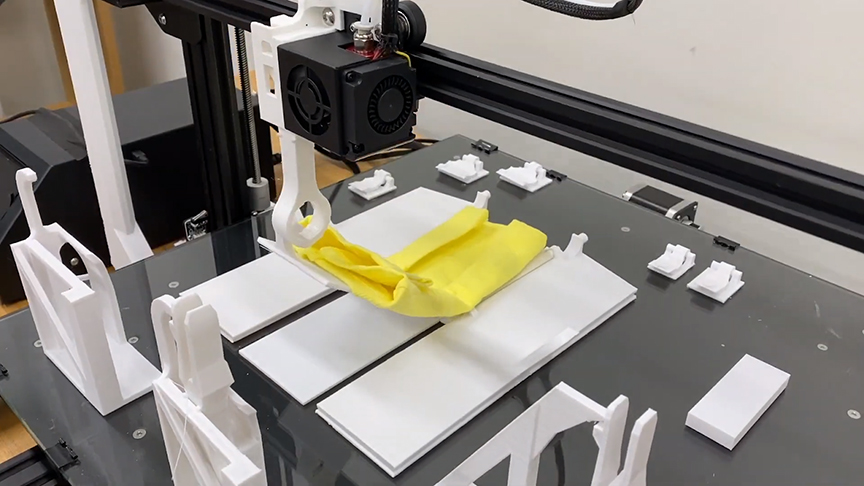

The very same printer was then used to remove the support of the printed parts, as well as move them to their correct locations in the assembly (on the print bed). This printing, support removal and assembly process requires no human interaction. Yes, you read that right.

Check out the video of the process below.

After the printer has printed the parts and assembled itself, the printer’s motion system is then used to drive the assembled Functograph, which uses the 3D printed assembly components to perform a variety of tasks, namely assembling and cutting sandwiches, and folding shirts.

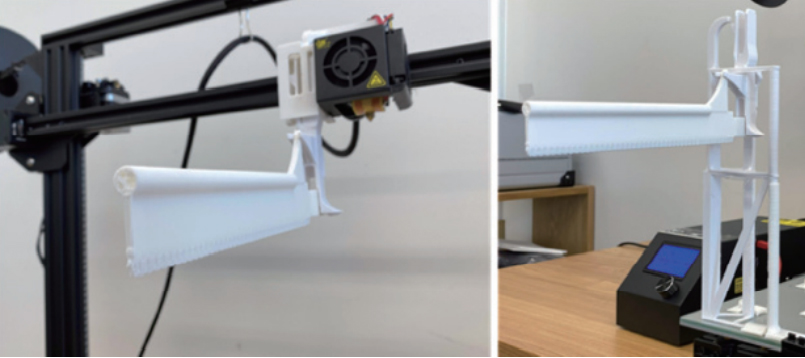

You can see the sandwich cutter mounted to the print head on the X-axis.

The cutting action is achieved by the movement of the print bed on the Y-axis, enabling the positioned plastic knife to saw through the sandwich.

Other tools in the process allow automated chopping of vegetables and meats, ham pick and place system, and other sandwich process related tasks.

In the pictures below you can see the cucumber chopping/feed process in action.

Folding Clothes

And when your printer has finished making your sandwiches, you can treat it to a few rounds of folding your clothes. Ah joy! What a time to be a machine!

While folding the clothes, the print head changes the end effectors to allow the head to perform different tasks.

You can see the whole process of printing and assembling the clothes process line in the video below.

In principle this project shows the concept of printed production lines, which you must admit, is pretty amazing especially given the number of processes achieved in such a small volume of the Functograph. And of course, the assembly components can be changed also, to do other things.

For now, the team is happy that they have demonstrated the device as a function generator (hence the name, Functograph). Put bread in…sandwiches come out. That’s a function.