No doubt, astute readers have heard of Simplify3D, even if they’ve never used their software. They cemented their place as one of the most famous producers of slicing software with innovative features like the Dual Extrusion Wizard and Interactive Print Simulations as part of their own eponymous software. Simplify3D are now looking to wow print enthusiasts with their new version 4.0 upgrade.

Version 4.0 is a free update for all existing users. It is available on their website and brings out a host of new features that add to this already solid software package. The goal of the company has always been to make 3D printing easier and smoother. This new software is no different. The general trend they follow is one that allows for every minutiae of setting to be controlled and to alter on command at the right time.

Variable Print Settings

The new variable print settings are probably the most exciting part of version 4.0. They enable users to divide their setting by section of the model. In this way, you can give each area of the eventual print a different series of settings to achieve the best results. Consequently, it allows for complex prints with shifting mechanical properties for each section. It is especially useful for prints with distinct sections that require varying features.

As the picture above illustrates, you can set zones of operation where users can vary up strength and weight. It also allows users to print faster by cutting out intense amounts of work on section that may not need it. The chess piece from the image above was printed 22% faster and with a better centre of gravity by optimising such settings.

Dynamic Feature Sizing

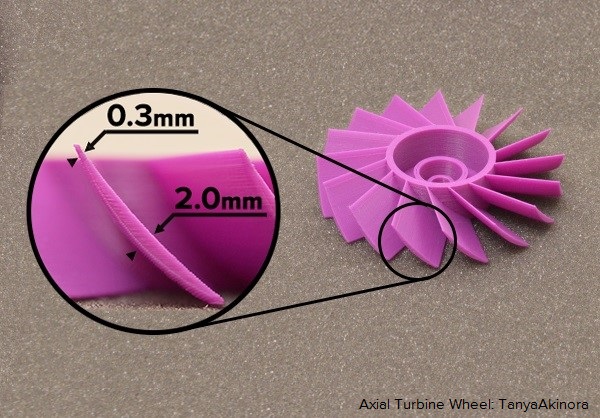

Another element that provides increased levels of control is the dynamic feature sizing option. This feature increases or decreases the amount of plastic used by the extruder depending on the needs of a particular section of the model. As a result, the extrusion process will change the thickness of a particular part of the total construction. This improves the minimum feature size of the printer and improves print accuracy.

This feature also allows for the dynamic gap fill option. This is a system where the software fills up empty spaces with a single dynamic extrusion. The software also takes the model interior into account and calibrates the best way to seal the walls. This greatly improves the strength of the print.

As the picture of the fan blade above shows, this features allows the printer to smoothly transition between thicknesses to better match the desired model. It allows a level of detail rivalling SLA and SLS.

Improved Supports and Foundations

Simplify3D have also added features to assist with complex print structures that may need additional foundations. These improvements allow for better supports, brims and rafts. Simplify3D have earned critical acclaim for their previous version support structure calibration system. It boasts bettering anchoring, the ability to vary up the densities near the print allowing for easier removal (as shown in the picture above) and filament usage reduction.

Simplify3D have also developed a system that creates breakaway rafts for simple removal. It is also resource efficient, saving 50% of the filament in 40% of the standard time. The foundations in version 4.0 are easy to tear off and do not interfere with the print itself due to how the algorithm structures densities. This is a welcome feature in any print software’s arsenal.

Other Additions

- Animated preview of the print process.

- New bridging algorithm.

- New dual extrusion options.

- Supports more 3D printer than ever before.